Izindaba

-

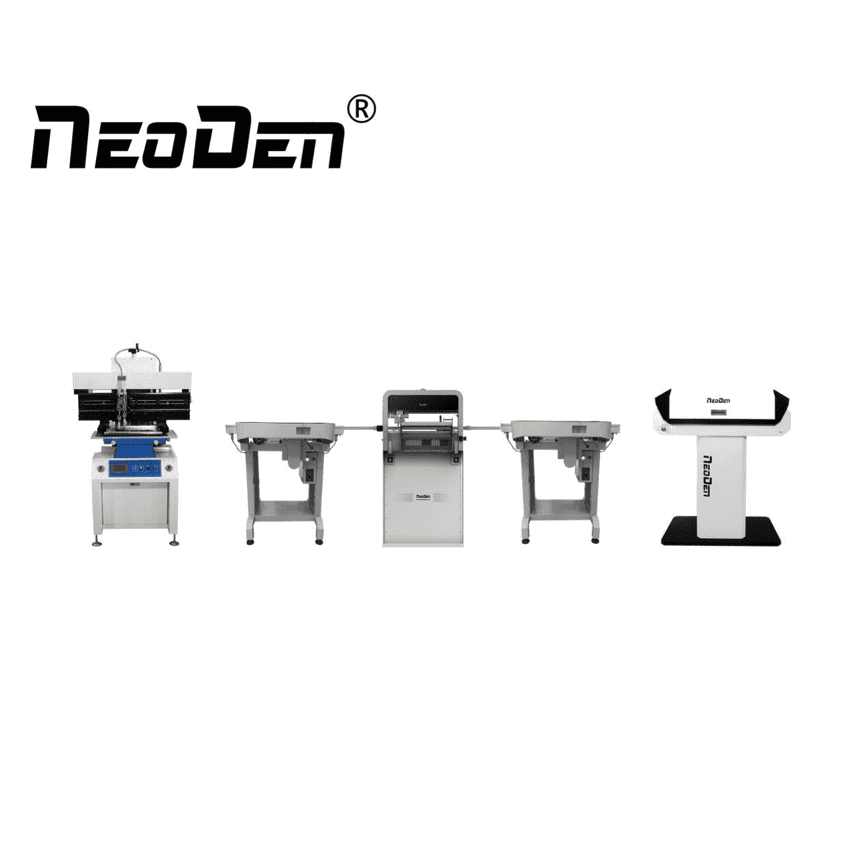

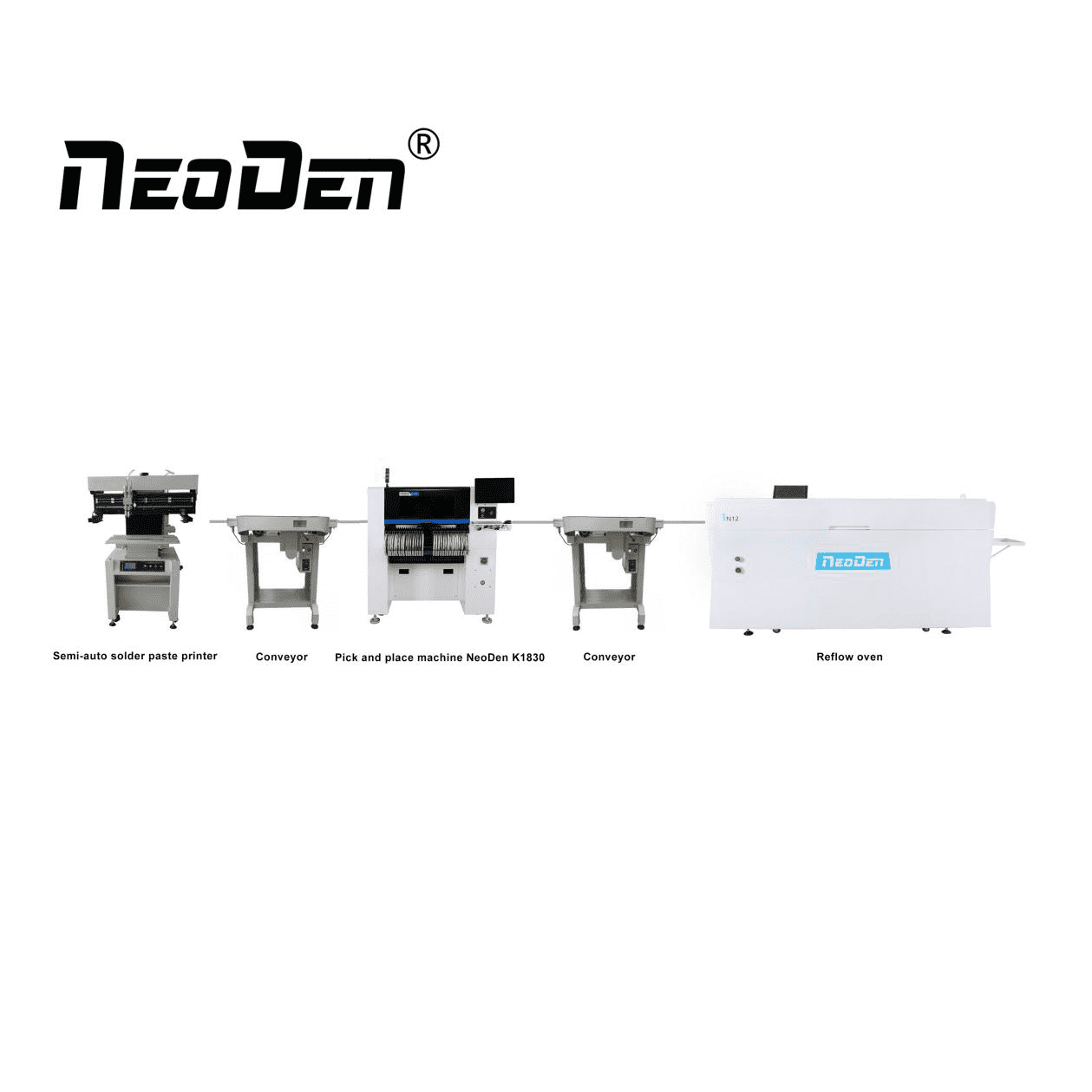

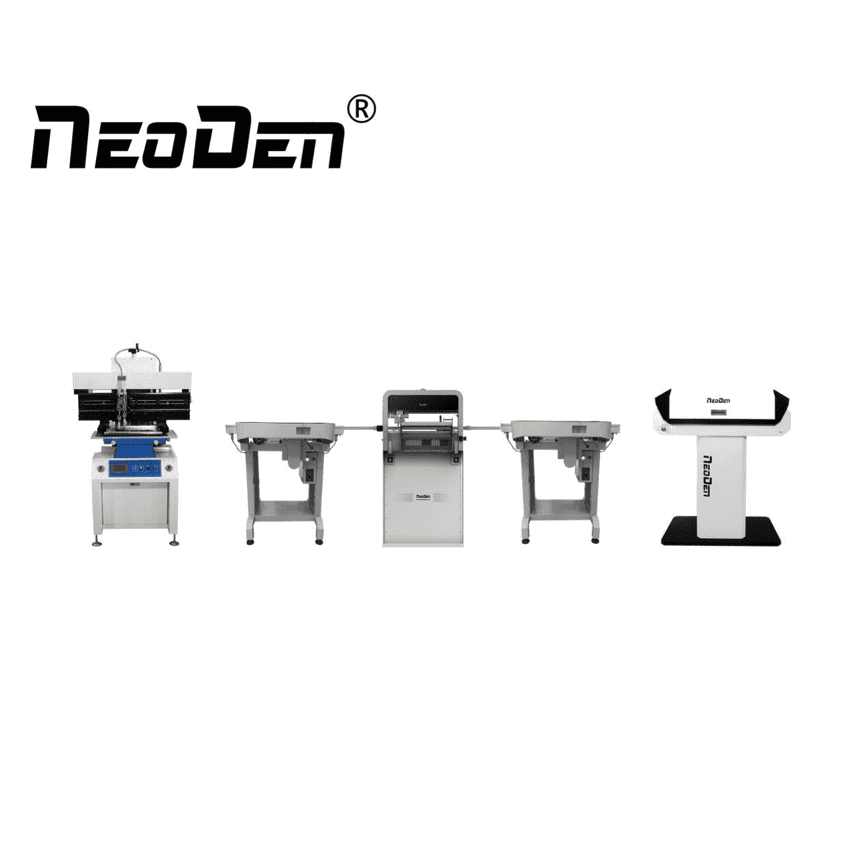

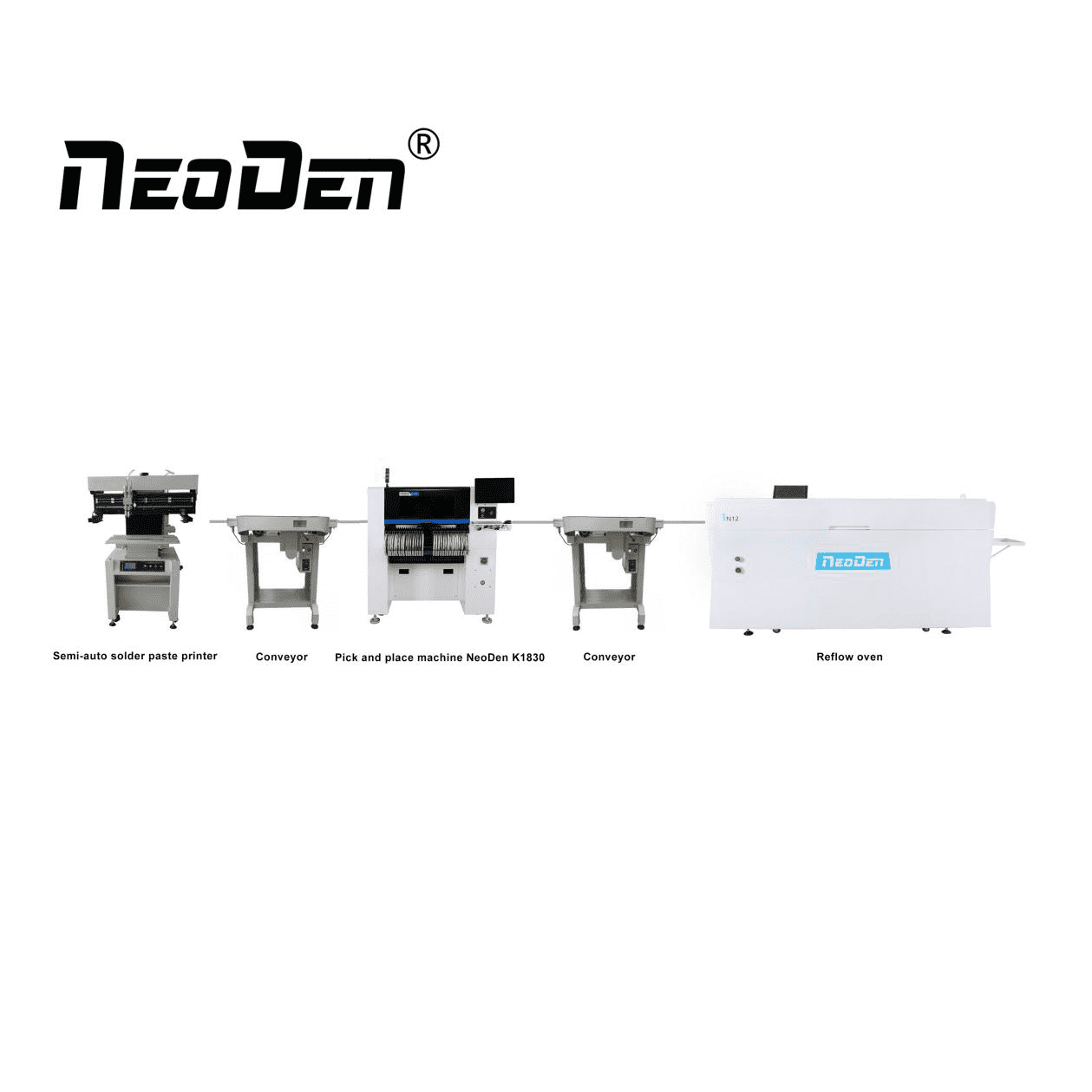

Ukwakhiwa komugqa wokukhiqiza we-SMT

Imigqa yokukhiqiza ye-SMT ingahlukaniswa ibe imigqa yokukhiqiza okuzenzakalelayo kanye nemigqa yokukhiqiza e-semi-automatic ngokwezinga lokuzenzekelayo, futhi ingahlukaniswa ngemigqa yokukhiqiza emikhulu, ephakathi nendawo kanye nemincane ngokobukhulu bomugqa wokukhiqiza.Ulayini wokukhiqiza ozenzakalelayo ngokugcwele ubhekisela...Funda kabanzi -

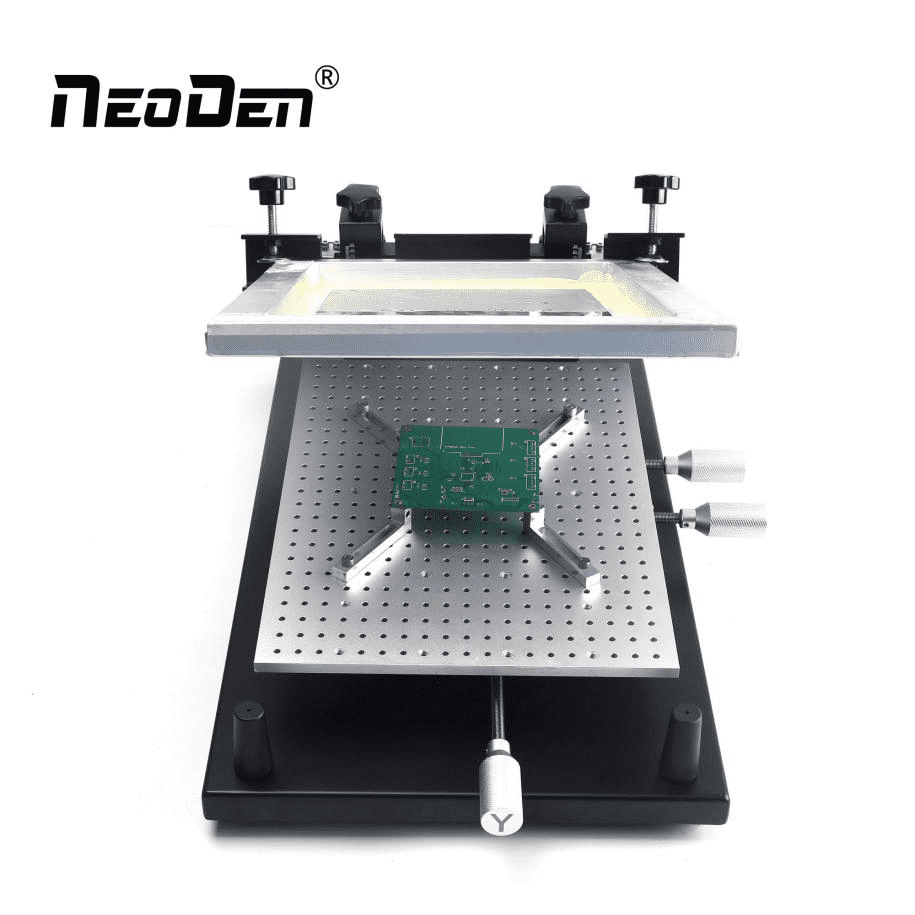

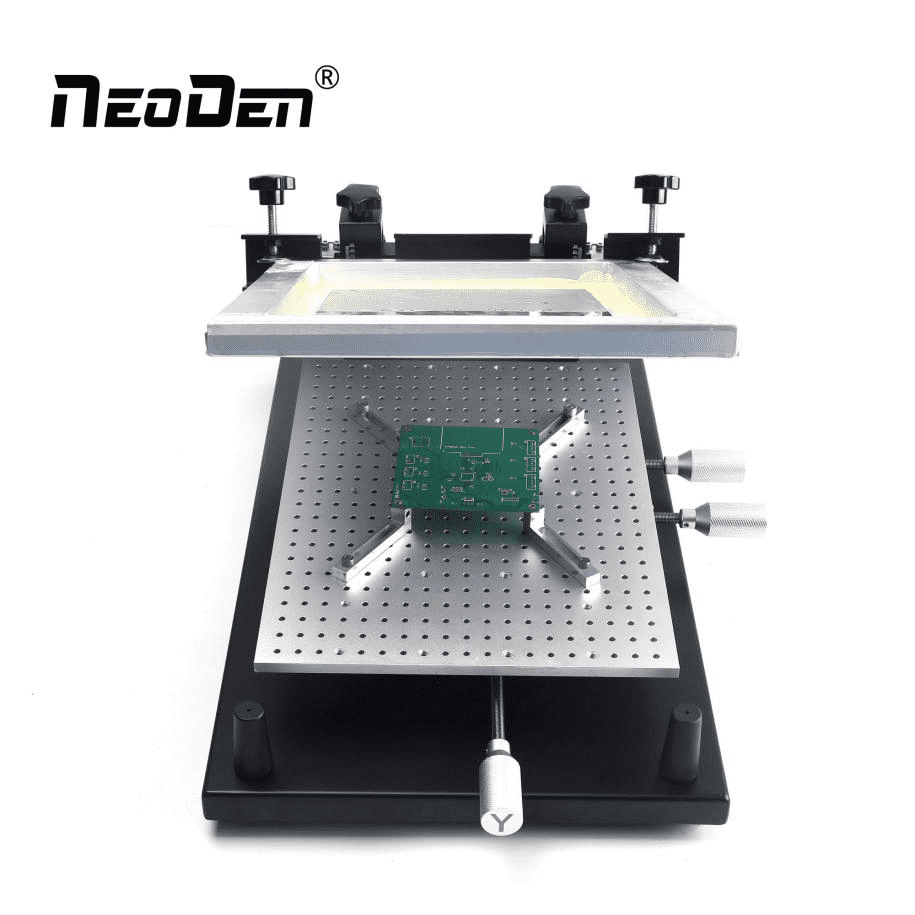

Iziphakamiso mayelana nokusebenza kwephrinta ye-solder eyenziwe ngesandla

Ukubeka kanye nokubeka indawo yephrinta ye-solder eyenziwa ngesandla Elayini wokukhiqiza we-SMT, ukuphrinta kuwukushibilikisa unamathisele we-solder kumaphedi ahambisanayo ku-PCB ukuze ulungiselele isiqeshana esilandelayo.Iphrinta ye-solder ye-manual ibhekisela kwinqubo yokuphrinta ngokunamathisela kwe-solder usebenzisa umshini wokuphrinta owenziwe ngesandla.I-o...Funda kabanzi -

Izinzuzo ze-AOI nokuhlola okwenziwa ngesandla

Umshini we-AOI umtshina othomathikhi, osebenzisa isimiso sokubona ukuskena ikhamera kudivayisi ye-PCB, ukuqoqa izithombe, ukuqhathanisa idatha ehlanganisiwe ye-solder nedatha efanelekile kusizindalwazi somshini, bese umaka ukushisela kwe-PCB enesici ngemva kokucubungula isithombe. .I-AOI ine-gre...Funda kabanzi -

Ukucushwa kwephrinta ebonakalayo ezenzakalelayo egcwele

Singumkhiqizo wokukhiqiza izinhlobo ezahlukene zamaphrinta e-solder.Nakhu okunye ukulungiselelwa Kwephrinta Ebonakalayo Egcwele Ezenzakalelayo.Ukucushwa Okujwayelekile Uhlelo olunembile lokuma kokubona: Indlela emine yomthombo wokukhanya iyalungiseka, ukushuba kokukhanya kuyalungiseka, ukukhanya kuyafana, futhi ukutholwa kwesithombe kungu-m...Funda kabanzi -

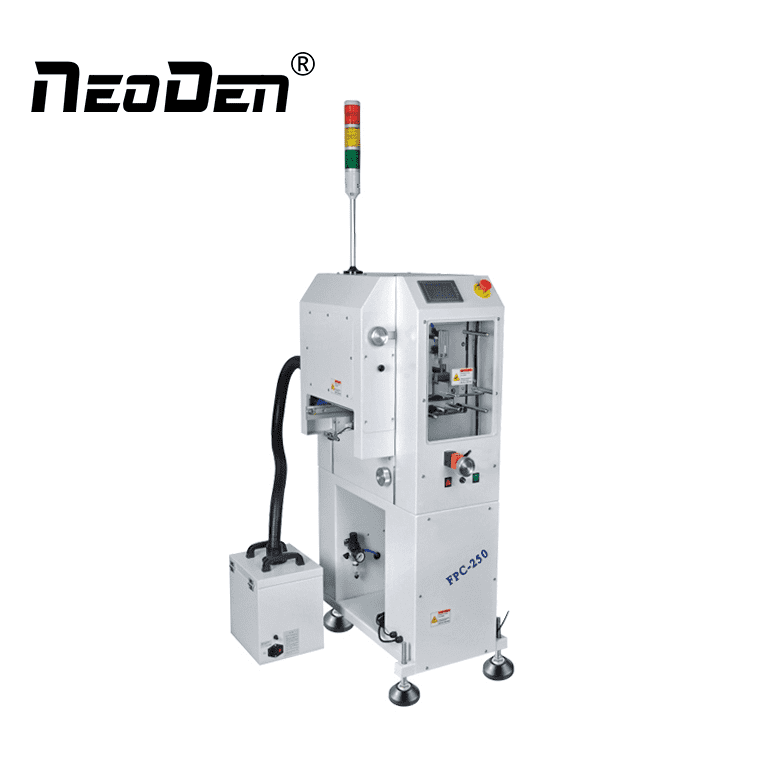

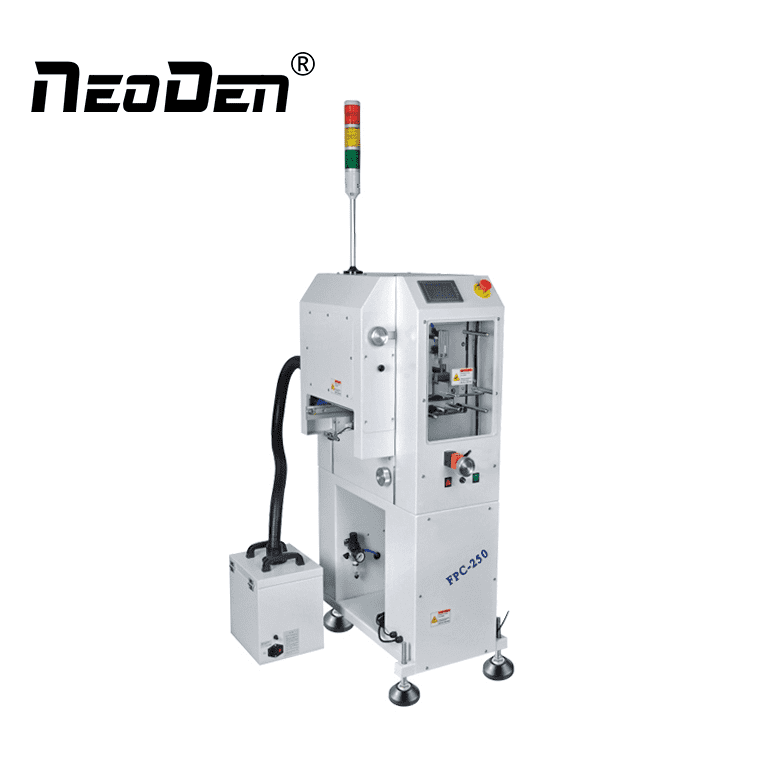

Indima yomshini wokuhlanza we-PCB

Umshini wokuhlanza i-PCB ungangena esikhundleni se-PCB yokuhlanza yokwenziwa, kanye nokwanda kokusebenza kahle nokuqinisekisa ikhwalithi yokuhlanza, kunokuhlanza okwenziwayo okulula kakhulu, isinqamuleli, umshini wokuhlanza i-PCB ukuhlanza ukugeleza okusalayo ngesixazululo, ubuhlalu bethini, uphawu olungcolile olumnyama, kanye kanjalo abanye...Funda kabanzi -

Ukuhlukaniswa kwe-AOI kanye nomgomo wesakhiwo ekukhiqizweni kwe-SMT

Ngokusetshenziswa okubanzi kwezingxenye ze-chip ezingu-0201 kanye nesekethe ehlanganisiwe engu-0.3 Pinch, amabhizinisi anezidingo eziphakeme neziphakeme zekhwalithi yomkhiqizo, ezingenakuqinisekiswa ngokuhlola okubonakalayo kuphela.Ngalesi sikhathi, ubuchwepheshe be-AOI buvela ngesikhathi esifanele.Njengelungu elisha lomkhiqizo we-SMT...Funda kabanzi -

Kungani udinga ukuhlanzwa kwe-PCB?

Okokuqala, ngithanda ukwethula umshini wethu wokuhlanza i-PCB kanye nomshini wokuhlanza wensimbi: Umshini wokuhlanza i-PCB umshini wokuhlanza i-brush roller uhlobo olulodwa.Isetshenziswa phakathi komshini wokuphrinta we-loader kanye ne-Stencil, ofanele izidingo zokuhlanza ze-AI kanye ne-SMT, ingafinyelela izidingo ze...Funda kabanzi -

Yiziphi izici zenqubo ye-reflow welding?

I-Reflow flow welding ibhekisela kwinqubo yokushisela eqaphela ukuxhumana kwemishini nokukagesi phakathi kweziphetho ze-solder noma izikhonkwane zezingxenye zokuhlanganisa ezingaphezulu kanye namaphedi e-PCB e-solder ngokuncibilikisa unamathisele we-solder ophrintwe ngaphambili kumaphedi okuthengisa we-PCB.1. Ukugeleza kwenqubo Inqubo yokugeleza kwe-reflow soldering: i-sol yokuphrinta...Funda kabanzi -

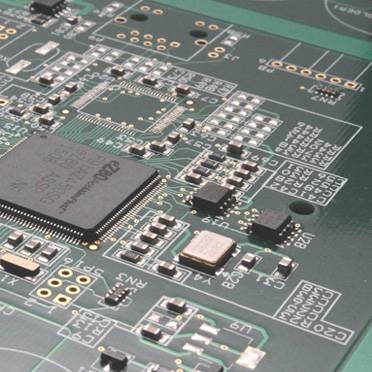

Yiziphi izinto zokusebenza nemisebenzi edingekayo ekukhiqizeni kwe-PCBA?

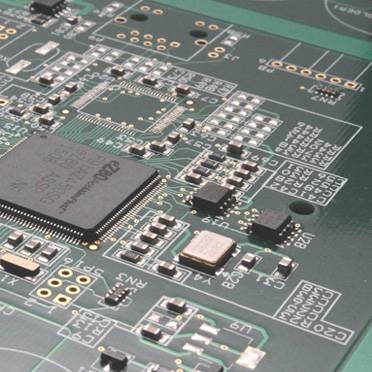

Ukukhiqizwa kwe-PCBA kudinga okokusebenza okuyisisekelo okufana nephrinta yokunamathisela yokunamathisela yokunamathisela ye-SMT, umshini we-SMT, ihhavini eligeleza kabusha, umshini we-AOI, umshini wokugunda iphinikhodi, i-wave soldering, isithando somlilo sethayela, umshini wokuwasha amapuleti, ukulungiswa kwe-ICT kokuhlolwa, ukulungiswa kwe-FCT, indawo yokuhlola ukuguga, njll. I-PCBA icubungula izitshalo zezinhlobo ezahlukene...Funda kabanzi -

Yimaphi amaphuzu okufanele anakwe ekucutshungulweni kwe-chip ye-SMT?

1.Isimo sesitoreji sokunamathisela kwe-solder Ukunamathisela kwe-Solder kufanele kusetshenziswe ekucubunguleni isichibi se-SMT.Uma i-solder paste ingasetshenziswa ngokushesha, kufanele ibekwe endaweni yemvelo ye-5-10 degrees, futhi izinga lokushisa akufanele libe ngaphansi kwama-degree angu-0 noma ngaphezulu kuka-10 degrees.2.Okubalulekile kwansuku zonke...Funda kabanzi -

I-Solder Namathisela i-mixer Ukufakwa nokusebenzisa

Sisanda kwethula i-solder paste mixer, ukufakwa nokusetshenziswa komshini wokunamathisela we-solder kuzochazwa kafushane ngezansi.Ngemva kokuthenga umkhiqizo, sizokunikeza incazelo ephelele yomkhiqizo.Sicela ukhululeke ukuxhumana nathi uma uludinga.Ngiyabonga.1.Ngicela ubeke i-mach...Funda kabanzi -

Izidingo eziyi-17 zokwakhiwa kwesakhiwo sengxenye kunqubo ye-SMT (II)

11. Izingxenye ezizwelayo ekucindezelekeni akufanele zibekwe emakhoneni, emaphethelweni, noma eduze nezixhumi, izimbobo ezifakwayo, ama-grooves, ama-cutouts, ama-gashes nasemakhoneni amabhodi esekethe aphrintiwe.Lezi zindawo ziyizindawo zokucindezeleka okukhulu kwamabhodi esekethe aphrintiwe, angabangela kalula imifantu noma imifantu emajoyini e-solder...Funda kabanzi