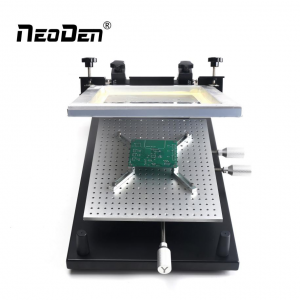

Ukubeka kanye nokubeka kweimanuwalii-solderphrintaer

Emgqeni wokukhiqiza we-SMT, ukuphrinta kuwukushelela unamathisele we-solder kumaphedi ahambisanayo ku-PCB ukuze ulungiselele isiqeshana esilandelayo.Iphrinta ye-solder ye-manual ibhekisela kwinqubo yokuphrinta ngokunamathisela kwe-solder usebenzisa umshini wokuphrinta owenziwe ngesandla.

Inqubo yokusebenza yephrinta ye-solder ye-manual ikakhulukazi ihlanganisa ukubeka amapuleti, ukuma, ukuphrinta, ukuthatha amapuleti kanyeukuhlanza insimbi yensimbi.

- I-mesh yensimbi engaguquki

Sebenzisa idivayisi yokulungisa ukulungisa insimbi yensimbi emshinini wokuphrinta.Ngemva kokulungisa, qinisekisa ukuthi insimbi yensimbi ne-PCB ixhumene nesicaba.Akukho ukuthintana okungalingani noma okuyingxenye eyodwa okungenzeka, ngaphandle kwalokho kulula ukubangela ukuwa kwephoyinti lokuphrinta le-solder, okuthinta ikhwalithi yokuphrinta kanye nempilo yesevisi yensimbi yensimbi. - Lena indawo ka-PCB

Ukuphrinta okwenziwa ngesandla, i-PCB ngokuvamile yamukela ukuma konqenqema lwepuleti, okungukuthi, ukuma ngokwendawo yembobo yokubeka ebhodini.Ngemuva kokumiswa, i-mesh yensimbi yensimbi kufanele iqondaniswe ngokunembile namaphedi ahambisanayo e-PCB.Ukuze ube nokubukeka okuhle kokuhlangana kwe-solder, ngokuvamile kuyadingeka ukuthi i-solder paste kanye ne-solder pad dislocation degree ibe ngaphansi kuka-10%.

Isandla siphrinte izinyathelo ezi-4

- Inqubo yokunyathelisa ngokuyinhloko inezinyathelo ezine ezilandelayo.

(1) izinga lokushisa nokuxuba okuhle kwe-solder okunamathiselwe okulinganiselwe futhi okunamathiselwe kunetha lensimbi, unamathisele we-solder ungathathi kakhulu, ngokuphrinta ngokuhlanganisa. - I-PCB ezophrintwa kufanele ibekwe endaweni efanele etafuleni lokuphrinta, ibeke phansi inetha lensimbi, futhi ihlole ukuthi ingabe inetha liqondaniswe kahle yini ne-PCB solder pad.

- Khwebula unamathisele we-solder nge-scraper ukuze wenze i-solder inamathise ku-roll net yensimbi bese uphrinta ukusuka phezulu kuye phansi ngendlela ye-PCB.

- Khipha i-PCB ephrintiwe etafuleni lokuphrinta.Hlola ukuthi ingabe kukhona ukuvuza, ithini eningi, ithini elincane, ngisho nesenzakalo sokuphrinta.Uma ungafaneleki, geza unamathisele we-solder ngebhodi lokuwasha bese uliphrinta kabusha ngemva kokuba ibhodi lomile.

Siphinde sihlinzekeiphrinta ye-semi-automatic solder, uma udinga, zizwe ukhululekile ukuxhumana nathi.

Isikhathi sokuthumela: Jan-21-2021