Izindaba

-

Yiziphi izici zenqubo ye-reflow welding?

I-Reflow flow welding ibhekisela kwinqubo yokushisela eqaphela ukuxhumana kwemishini nokukagesi phakathi kweziphetho ze-solder noma izikhonkwane zezingxenye zokuhlanganisa ezingaphezulu kanye namaphedi e-PCB e-solder ngokuncibilikisa unamathisele we-solder ophrintwe ngaphambili kumaphedi okuthengisa we-PCB.1. Ukugeleza kwenqubo Inqubo yokugeleza kwe-reflow soldering: i-sol yokuphrinta...Funda kabanzi -

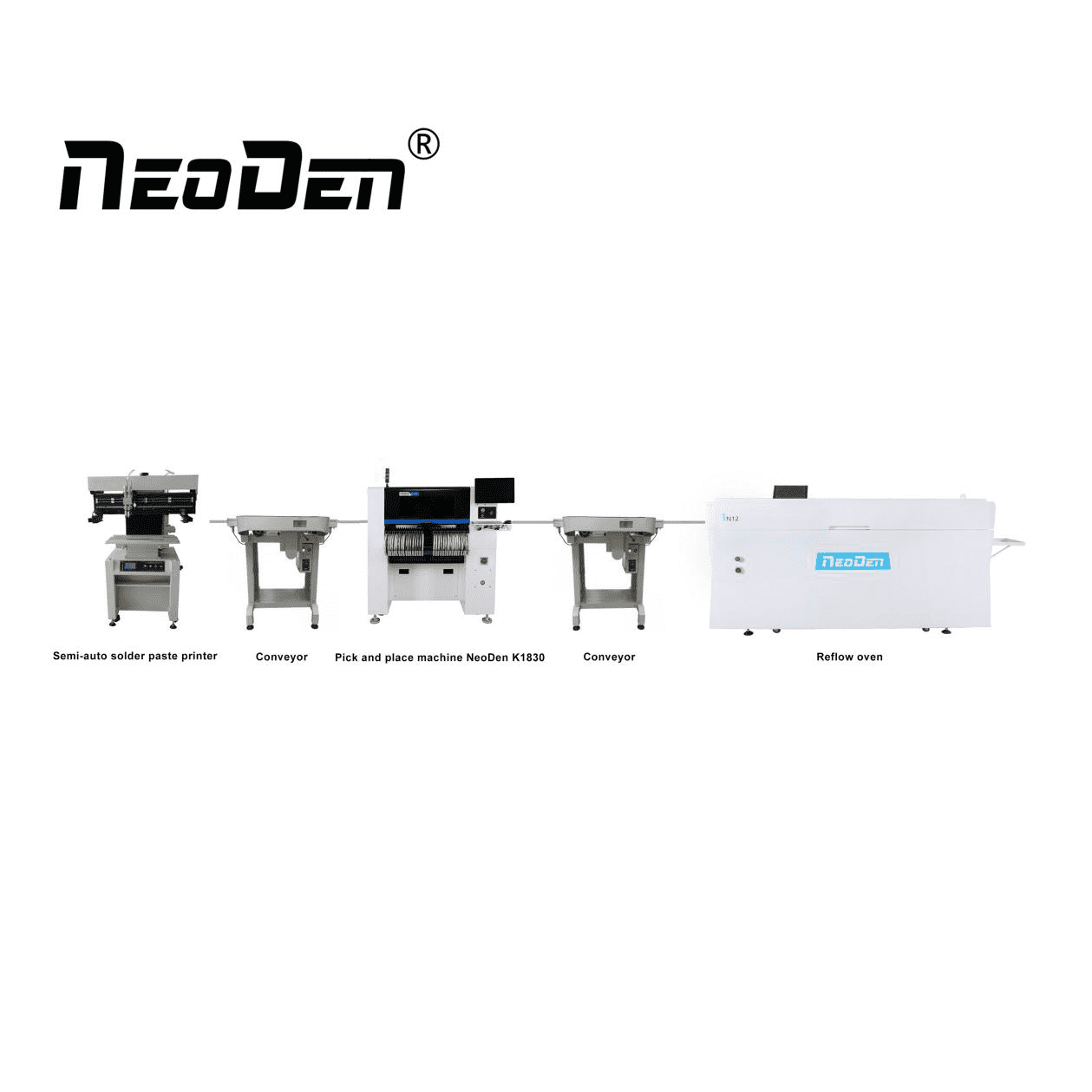

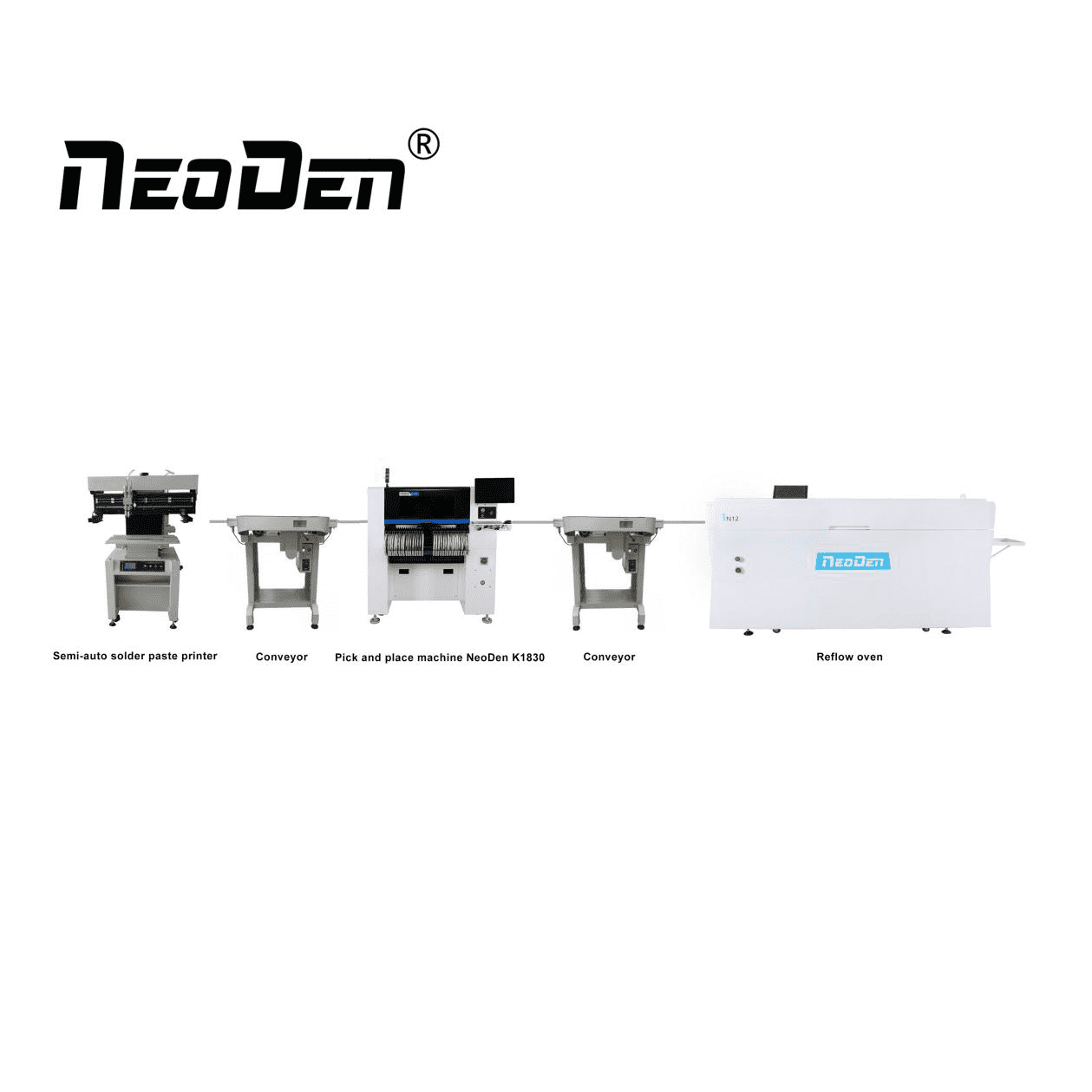

Yiziphi izinto zokusebenza nemisebenzi edingekayo ekukhiqizeni kwe-PCBA?

Ukukhiqizwa kwe-PCBA kudinga okokusebenza okuyisisekelo okufana nephrinta yokunamathisela yokunamathisela yokunamathisela ye-SMT, umshini we-SMT, ihhavini eligeleza kabusha, umshini we-AOI, umshini wokugunda iphinikhodi, i-wave soldering, isithando somlilo sethayela, umshini wokuwasha amapuleti, ukulungiswa kwe-ICT kokuhlolwa, ukulungiswa kwe-FCT, indawo yokuhlola ukuguga, njll. I-PCBA icubungula izitshalo zezinhlobo ezahlukene...Funda kabanzi -

Yimaphi amaphuzu okufanele anakwe ekucutshungulweni kwe-chip ye-SMT?

1.Isimo sesitoreji sokunamathisela kwe-solder Ukunamathisela kwe-Solder kufanele kusetshenziswe ekucubunguleni isichibi se-SMT.Uma i-solder paste ingasetshenziswa ngokushesha, kufanele ibekwe endaweni yemvelo ye-5-10 degrees, futhi izinga lokushisa akufanele libe ngaphansi kwama-degree angu-0 noma ngaphezulu kuka-10 degrees.2.Okubalulekile kwansuku zonke...Funda kabanzi -

I-Solder Namathisela i-mixer Ukufakwa nokusebenzisa

Sisanda kwethula i-solder paste mixer, ukufakwa nokusetshenziswa komshini wokunamathisela we-solder kuzochazwa kafushane ngezansi.Ngemva kokuthenga umkhiqizo, sizokunikeza incazelo ephelele yomkhiqizo.Sicela ukhululeke ukuxhumana nathi uma uludinga.Ngiyabonga.1.Ngicela ubeke i-mach...Funda kabanzi -

Izidingo eziyi-17 zokwakhiwa kwesakhiwo sengxenye kunqubo ye-SMT (II)

11. Izingxenye ezizwelayo ekucindezelekeni akufanele zibekwe emakhoneni, emaphethelweni, noma eduze nezixhumi, izimbobo ezifakwayo, ama-grooves, ama-cutouts, ama-gashes nasemakhoneni amabhodi esekethe aphrintiwe.Lezi zindawo ziyizindawo zokucindezeleka okukhulu kwamabhodi esekethe aphrintiwe, angabangela kalula imifantu noma imifantu emajoyini e-solder...Funda kabanzi -

Izinyathelo Zokuphepha Komshini we-SMT

Hlanza umgomo wenethi usebenzisa indwangu ukuthinta utshwala ukuze uhlanze, awukwazi ukuthela utshwala ngqo kunetha lensimbi nokunye.Kudingeka ukuya kuhlelo olusha ukuze uhlole isikhundla sokushaywa kwe-scraper yokuphrinta isikhathi ngasinye.Zombili izinhlangothi ze-y-direction scraper stroke kufanele zidlule ...Funda kabanzi -

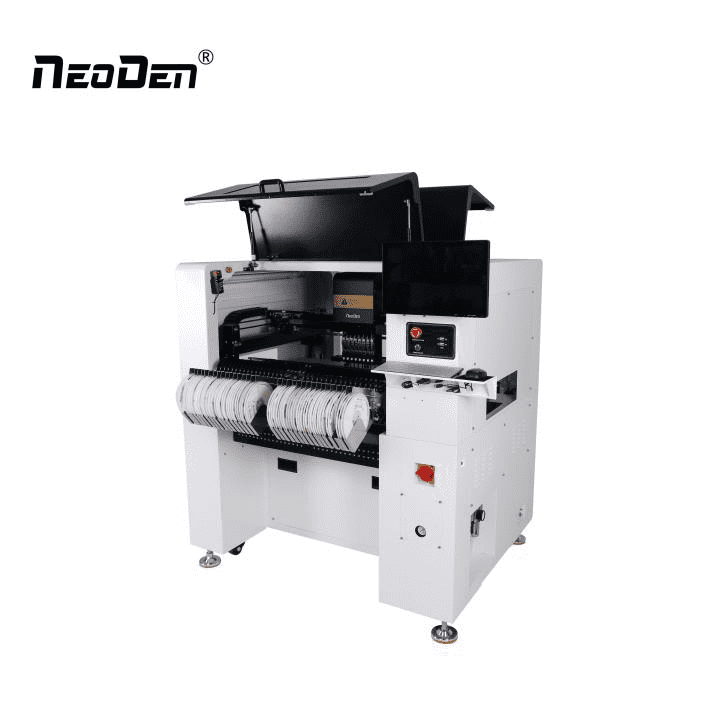

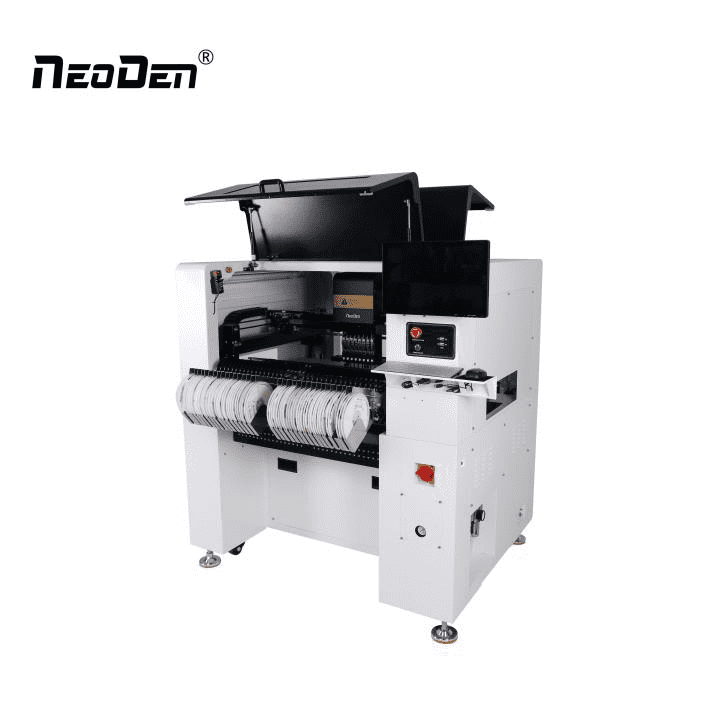

Iqhaza nokukhethwa kwe-compressor yomoya yomshini wokubekwa kwe-SMT

Umshini wokukhetha nokubeka we-SMT owaziwa nangokuthi "umshini wokubeka" kanye "nohlelo lokubeka indawo", iyithuluzi lokubeka izingxenye zokubeka phezulu ngokunembile ku-PCB solder plate ngokuhambisa ikhanda lokubeka ngemva kokukhipha umshini noma iphrinta ye-stencil endaweni yokukhiqiza. .Funda kabanzi -

Indawo yomshini we-SMT AOI kulayini wokukhiqiza we-SMT

Nakuba umshini we-SMT AOI ungasetshenziswa ezindaweni eziningi emugqeni wokukhiqiza we-SMT ukuze kutholwe amaphutha athile, okokusebenza kokuhlola kwe-AOI kufanele kubekwe endaweni lapho ukukhubazeka okuningi kungabonakala futhi kulungiswe ngokushesha ngangokunokwenzeka.Kunezindawo ezintathu zokuhlola eziyinhloko: Ngemva kokuthengisa...Funda kabanzi -

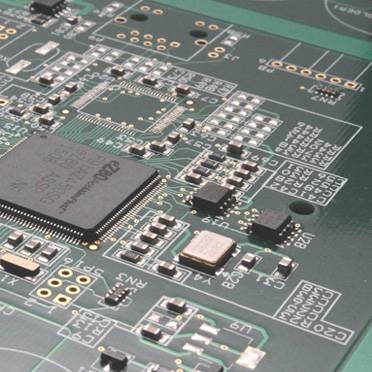

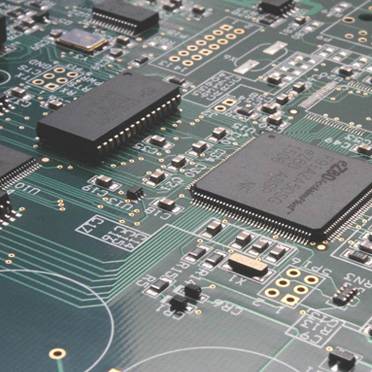

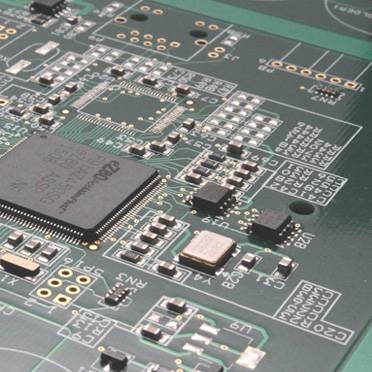

Izidingo eziyi-17 zokwakhiwa kwesakhiwo sengxenye kunqubo ye-SMT (I)

1. Izidingo eziyisisekelo zenqubo ye-SMT yokwakheka kwengxenye yesakhiwo zimi kanje: Ukusatshalaliswa kwezingxenye ebhodini lesekethe eliphrintiwe kufanele kufane ngangokunokwenzeka.Umthamo wokushisa we-reflow soldering wezingxenye ezinkulu zekhwalithi mkhulu, futhi ukugxila ngokweqile kulula uku...Funda kabanzi -

I-PCB ifekthri ilawula kanjani ikhwalithi yebhodi le-PCB

Ikhwalithi ingukusinda kwebhizinisi, uma isilawuli sekhwalithi singekho, inkampani ngeke ihambe kude, imboni ye-PCB uma ufuna ukulawula ikhwalithi yebhodi le-PCB, ungalawula kanjani?Sifuna ukulawula ikhwalithi yebhodi le-PCB, kufanele kube nohlelo lokulawula ikhwalithi, ngokuvamile kuthiwa ...Funda kabanzi -

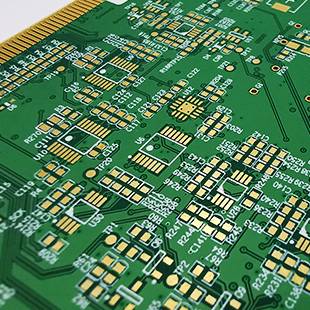

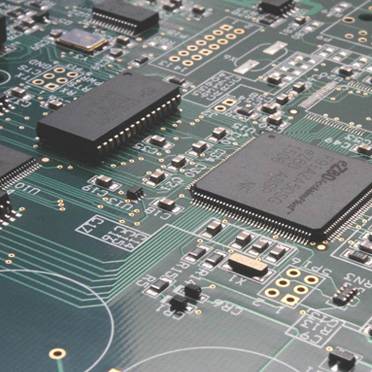

Isingeniso ku-PCB substrate

Ukuhlukaniswa kwama-substrate Izinto ezijwayelekile zebhodi eliphrintiwe zingahlukaniswa zibe izigaba ezimbili: izinto eziqinile ze-substrate nezinto eziguquguqukayo ze-substrate.Uhlobo olubalulekile lwezinto ezijwayelekile eziqinile ze-substrate yi-copper clad laminate.Yenziwe nge-Reinforeing Material, i-inregnated wit...Funda kabanzi -

Izindawo zokushisa eziyi-12 ze-SMT Reflow oven I-NeoDen IN12 iyathengiswa ngokushisayo!

I-NeoDen IN12, ebesiyilindile unyaka wonke, ithole imibuzo yamakhasimende amasha namadala avela emhlabeni wonke.Uma ufuna ukuthenga ihhavini lokugeleza kabusha kwe-SMT, i-NeoDen IN12 izoba yisinqumo sakho esingcono kakhulu!Nazi ezinye zezinzuzo zehhavini yokugeleza komoya oshisayo.Ukuze uthole ulwazi olwengeziwe, sicela uzizwe ukhululekile ...Funda kabanzi