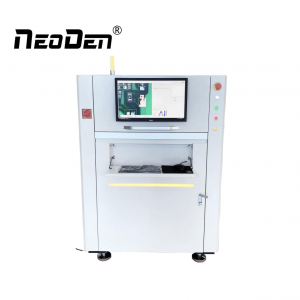

NgenkathiUmshini we-SMT AOIingasetshenziswa ezindaweni eziningi emugqeni wokukhiqiza we-SMT ukuze kutholwe amaphutha athile, okokusebenza kokuhlola kwe-AOI kufanele kubekwe endaweni lapho ukukhubazeka okuningi kungabonakala futhi kulungiswe ngokushesha ngangokunokwenzeka.Kunezindawo ezintathu zokuhlola eziyinhloko:

NgenkathiUmshini we-SMT AOIingasetshenziswa ezindaweni eziningi emugqeni wokukhiqiza we-SMT ukuze kutholwe amaphutha athile, okokusebenza kokuhlola kwe-AOI kufanele kubekwe endaweni lapho ukukhubazeka okuningi kungabonakala futhi kulungiswe ngokushesha ngangokunokwenzeka.Kunezindawo ezintathu zokuhlola eziyinhloko:

Ngemuva kokuthi i-solder paste iphrintiwe

Uma inqubo yokuphrinta yokunamathisela i-solder ihlangabezana nezidingo, inani lamaphutha e-ICT lingancishiswa kakhulu.Izinkinga zokuphrinta ezijwayelekile zihlanganisa okulandelayo:

A.Ithayela lokunamathisela elinganele kuiphrinta ye-stencil.

B. I-solder eningi kakhulu ku-solder pad.

C. Ukuqondana okungalungile kwe-solder ku-solder pad.

D. Solder ibhuloho phakathi pads.

Ku-ICT, amathuba okuba neziphambeko ngokuhlobene nalezi zimo alingana ngokuqondile nobucayi besimo.Ithini elincane alivamile ukuholela ekulimaleni, kuyilapho izimo ezinzima, njengethayela eliyisisekelo, cishe njalo ziholela ekulimaleni kwe-ICT.I-solder enganele ingaba yimbangela yokulahlekelwa kwengxenye noma ama-solder avulekile ahlangene.Nokho, ukunquma ukuthi ibekwe kuphi i-AOI kudinga ukuqaphela ukuthi ingxenye yokulahlekelwa kungenzeka ngenxa yezinye izizathu okufanele zifakwe ohlelweni lokuhlola.Lokhu kuhlolwa kwendawo kusekela ngokuqondile ukulandelwa kwenqubo nokuhlukaniswa kwezinhlamvu.Idatha yokulawula inqubo yokulinganisa kulesi sigaba ihlanganisa ukuphrinta kwe-offset kanye nolwazi lwevolumu ye-solder, kuyilapho ulwazi lwekhwalithi mayelana ne-solder ephrintiwe lukhiqizwa.

Ngaphambi kwereflow oven

Ukuhlolwa kwenziwa ngemva kokuba ingxenye ibekwe ku-solder unama ebhodini nangaphambi kokuba i-PCB idliwe esithandweni sokugeleza kabusha.Lena indawo evamile yokubeka umshini wokuhlola, njengoba iziphambeko eziningi ezivela ekunyatheliseni kokunamathisela kwe-solder nokubekwa komshini zingatholakala lapha.Ulwazi lokulawula inqubo yobuningi olukhiqizwa kule ndawo luhlinzeka ngolwazi lokulinganiswa kwemishini ye-chip enesivinini esikhulu kanye nempahla yokukhweza yezingxenye ezisondelene.Lolu lwazi lungasetshenziselwa ukuguqula ukubekwa kwengxenye noma ubonise ukuthi isikhwezi sidinga ukulinganisa.Ukuhlolwa kwale ndawo kuhlangabezana nomgomo wokulandela umkhondo wenqubo.

Ngemuva kwe-reflow soldering

Hlola ekupheleni kwenqubo ye-SMT, okuyindlela ethandwa kakhulu ye-AOI, ngoba kulapho wonke amaphutha enhlangano engatholakala khona.Ukuhlolwa kwe-post-reflow kunikeza izinga eliphezulu lokuphepha ngoba kuhlonza amaphutha abangelwa ukuphrinta kwe-solder paste, ukukhwezwa kwengxenye, kanye nenqubo yokugeleza kabusha.

Isikhathi sokuthumela: Dec-11-2020