Izindaba

-

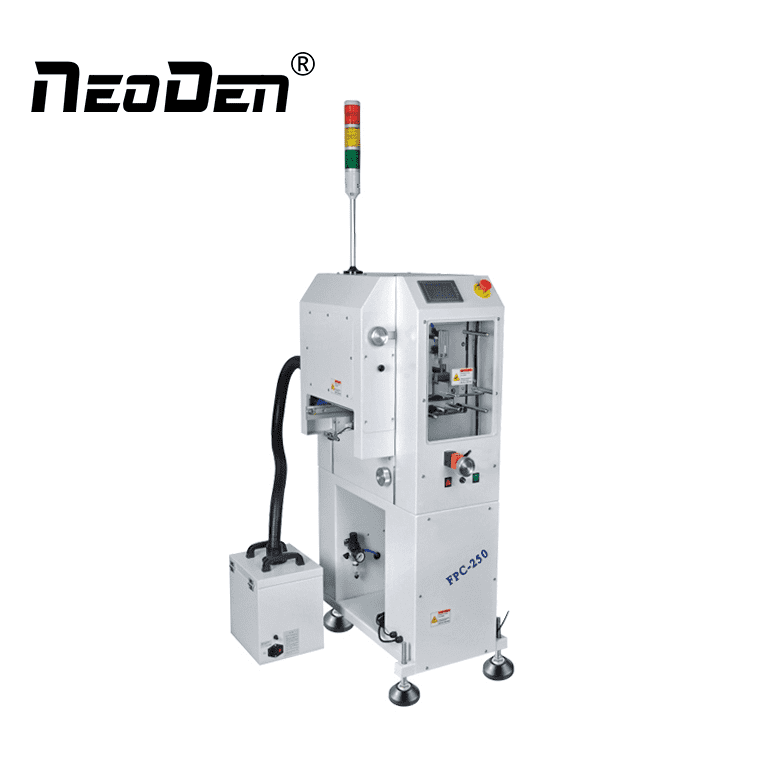

Umshini wokubeka izingxenye eziyisithupha

Ngokuvamile sisebenzisa umshini we-SMT wakhiwe izingxenye eziyisithupha, okulandelayo kuyincazelo emfushane kuwe: Ithebula elisebenzayo: Isetshenziswa njengezingxenye eziyisisekelo zokukhiqiza, ukufakwa nokusekelwa komshini wokukhweza.Ngakho-ke, kufanele ibe namandla anele okusekela.Uma ukwesekwa kunamandla...Funda kabanzi -

Ungakuvimbela kanjani ukwehluleka komshini we-SMT

Sivame ukusetshenziswa emshinini wokukhiqiza wokukhiqiza wokukhiqiza, umshini we-SMT ungowomshini ohlakaniphile, owusizo kakhulu, kodwa ngenxa yenqubo yokukhiqiza, asifaneleki ukusebenzisa, kulula ukubangela ukulimala komshini noma ukungasebenzi, ngakho-ke ukuze sigweme. sidinga ukunikeza umshini ukuze av...Funda kabanzi -

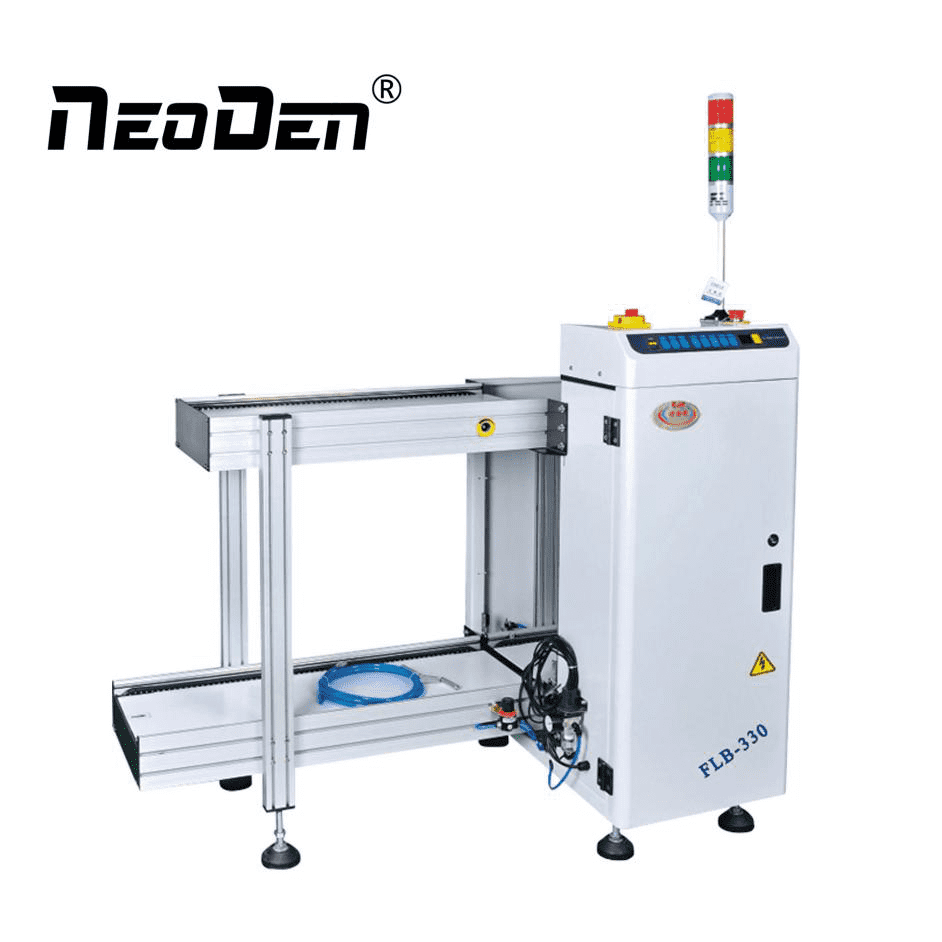

Umsebenzi nokugeleza kokusebenza kwesilayishi se-SMT

Indima yesilayishi se-SMT SMT PCB isilayishi iwuhlobo lwemishini yokukhiqiza edingekayo kulayini wokukhiqiza we-SMT.Umsebenzi wayo oyinhloko ukubeka ibhodi le-PCB elinganamathiselwe emshinini wokufaka ipuleti le-SMT bese uphakela ngokuzenzakalelayo ibhodi emshinini wepuleti lokumunca.Bese umshini wepuleti lokumunca uzozenzakalela...Funda kabanzi -

Isaziso Seholide saseNeoDen

Funda kabanzi -

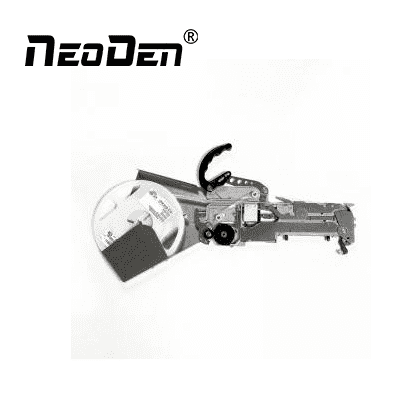

Ukuhlaziywa kwamaphutha okujwayelekile kanye nesixazululo se-SMT Feeder

Ngesikhathi sokukhiqizwa kwe-SMT, umshini we-SMT uvame ukuhlangana nezinkinga ezithile, ezithinta ukusebenza kahle nokukhiqiza kwesichibi.Emkhiqizweni we-patch, i-SMT Feeder iyingxenye evame kakhulu enezinkinga.Okulandelayo ukukusiza uhlaziye ukwehluleka okuvamile nezisombululo zomshini we-SMT, Sithemba ukuthi...Funda kabanzi -

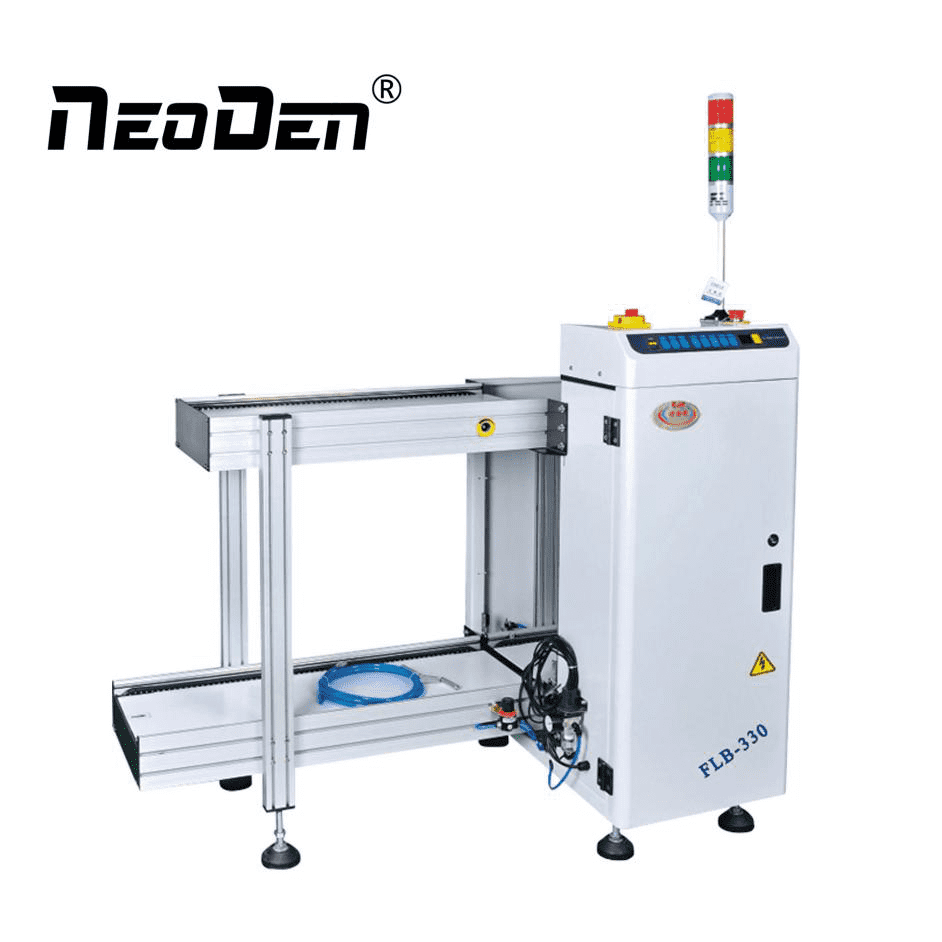

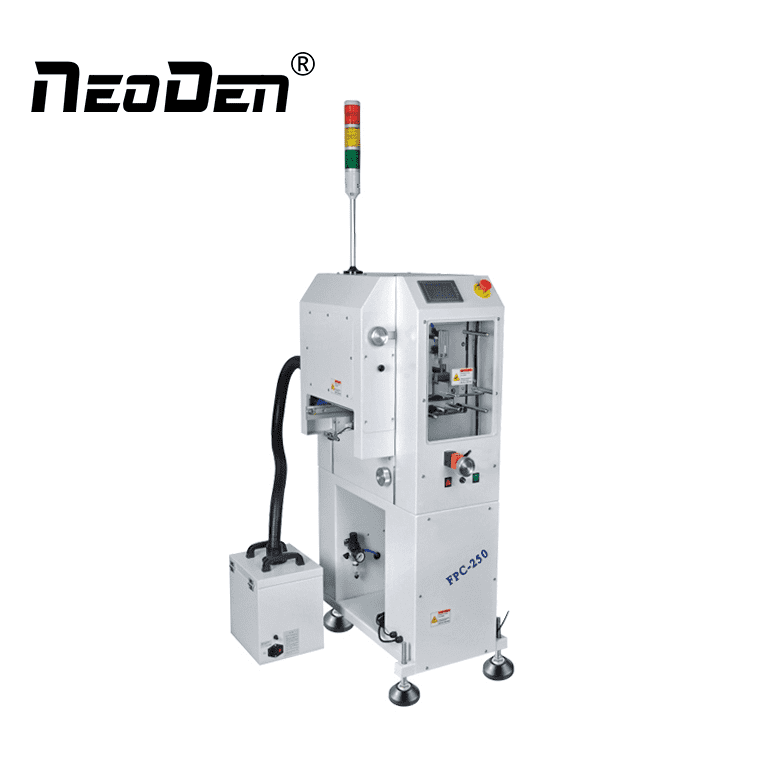

Isethulo somugqa wokukhiqiza we-Neoden PCB othomathikhi

I-PCB loader 1, Idizayini eqinile futhi ezinzile.2, uhlelo lokulawula lwe-PLC.3, Light touch LED ulwelwesi switch noma touch screen control panel 4, ongakhetha etholakalayo 5, Top naphansi izinsimbi womoya ukuze uvikele umagazini yokubeka 6, Ingcindezi elawulwa on pusher sika ukuvimbela umonakalo ibhodi 7, Self diagnostic iphutha ikhodi d...Funda kabanzi -

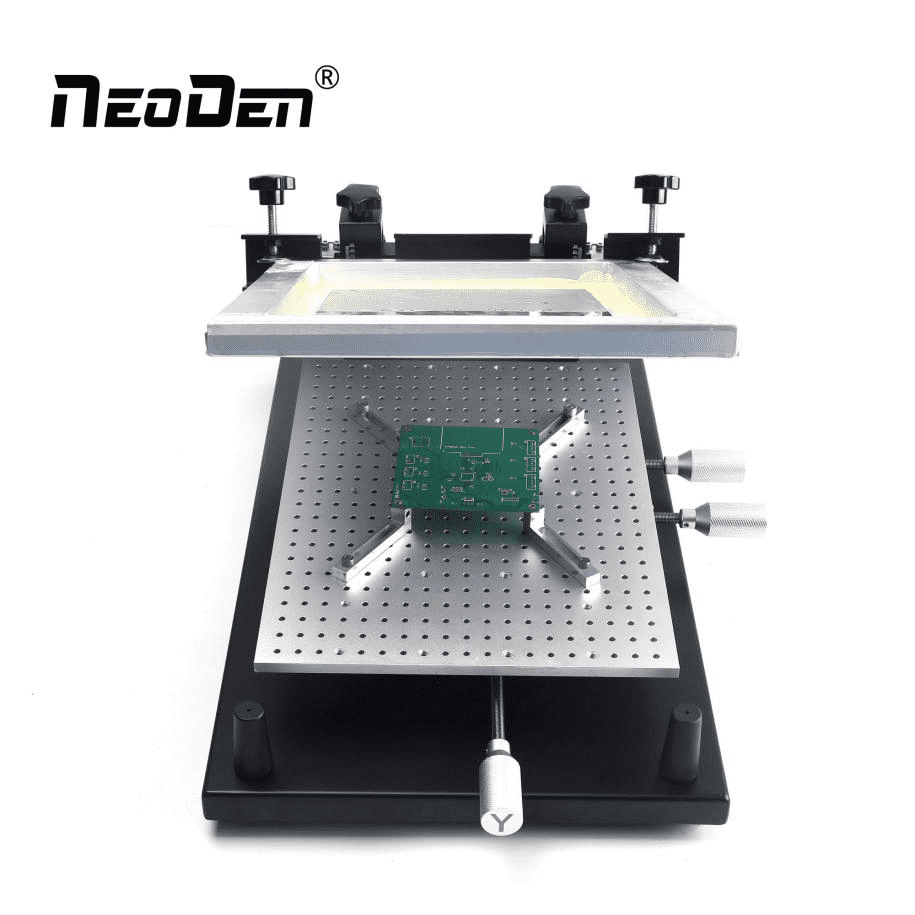

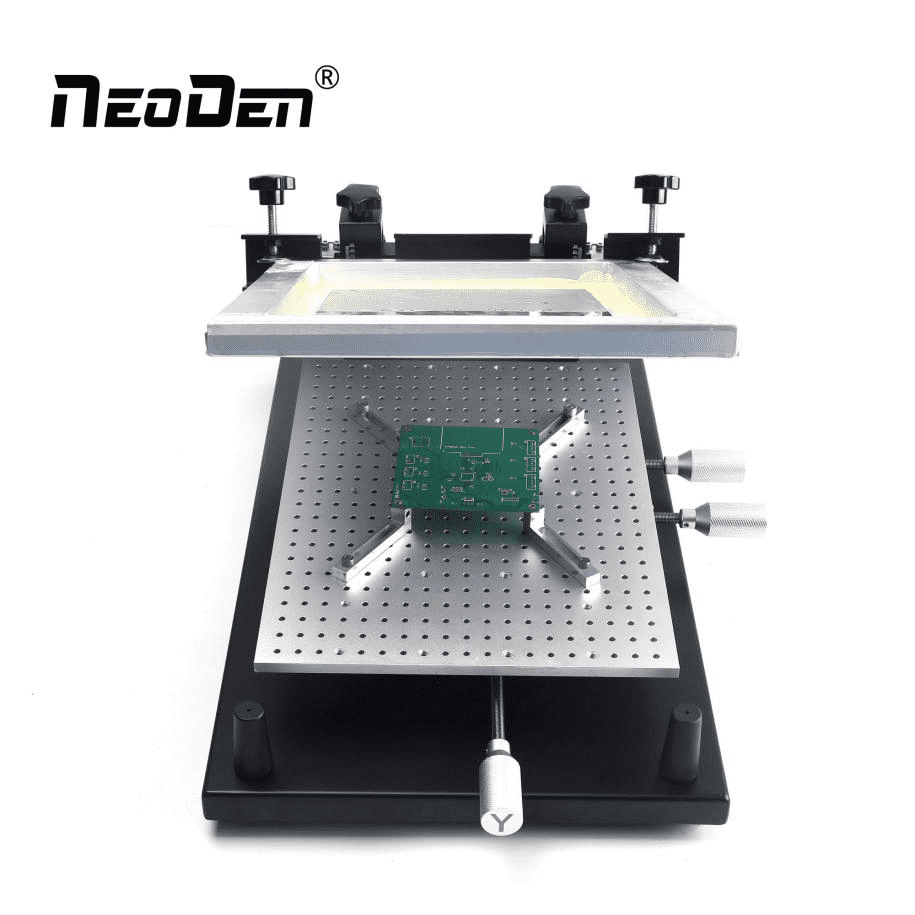

Iziphakamiso mayelana nokusebenza kwephrinta ye-solder eyenziwe ngesandla

Ukubeka kanye nokubeka indawo yephrinta ye-solder eyenziwa ngesandla Elayini wokukhiqiza we-SMT, ukuphrinta kuwukushibilikisa unamathisele we-solder kumaphedi ahambisanayo ku-PCB ukuze ulungiselele isiqeshana esilandelayo.Iphrinta ye-solder ye-manual ibhekisela kwinqubo yokuphrinta ngokunamathisela kwe-solder usebenzisa umshini wokuphrinta owenziwe ngesandla.I-o...Funda kabanzi -

Izinzuzo ze-AOI nokuhlola okwenziwa ngesandla

Umshini we-AOI umtshina othomathikhi, osebenzisa isimiso sokubona ukuskena ikhamera kudivayisi ye-PCB, ukuqoqa izithombe, ukuqhathanisa idatha ehlanganisiwe ye-solder nedatha efanelekile kusizindalwazi somshini, bese umaka ukushisela kwe-PCB enesici ngemva kokucubungula isithombe. .I-AOI ine-gre...Funda kabanzi -

Ukucushwa kwephrinta ebonakalayo ezenzakalelayo egcwele

Singumkhiqizo wokukhiqiza izinhlobo ezahlukene zamaphrinta e-solder.Nakhu okunye ukulungiselelwa Kwephrinta Ebonakalayo Egcwele Ezenzakalelayo.Ukucushwa Okujwayelekile Uhlelo olunembile lokuma kokubona: Indlela emine yomthombo wokukhanya iyalungiseka, ukushuba kokukhanya kuyalungiseka, ukukhanya kuyafana, futhi ukutholwa kwesithombe kungu-m...Funda kabanzi -

Indima yomshini wokuhlanza we-PCB

Umshini wokuhlanza i-PCB ungangena esikhundleni se-PCB yokuhlanza yokwenziwa, kanye nokwanda kokusebenza kahle nokuqinisekisa ikhwalithi yokuhlanza, kunokuhlanza okwenziwayo okulula kakhulu, isinqamuleli, umshini wokuhlanza i-PCB ukuhlanza ukugeleza okusalayo ngesixazululo, ubuhlalu bethini, uphawu olungcolile olumnyama, kanye kanjalo abanye...Funda kabanzi -

Ukuhlukaniswa kwe-AOI kanye nomgomo wesakhiwo ekukhiqizweni kwe-SMT

Ngokusetshenziswa okubanzi kwezingxenye ze-chip ezingu-0201 kanye nesekethe ehlanganisiwe engu-0.3 Pinch, amabhizinisi anezidingo eziphakeme neziphakeme zekhwalithi yomkhiqizo, ezingenakuqinisekiswa ngokuhlola okubonakalayo kuphela.Ngalesi sikhathi, ubuchwepheshe be-AOI buvela ngesikhathi esifanele.Njengelungu elisha lomkhiqizo we-SMT...Funda kabanzi -

Kungani udinga ukuhlanzwa kwe-PCB?

Okokuqala, ngithanda ukwethula umshini wethu wokuhlanza i-PCB kanye nomshini wokuhlanza wensimbi: Umshini wokuhlanza i-PCB umshini wokuhlanza i-brush roller uhlobo olulodwa.Isetshenziswa phakathi komshini wokuphrinta we-loader kanye ne-Stencil, ofanele izidingo zokuhlanza ze-AI kanye ne-SMT, ingafinyelela izidingo ze...Funda kabanzi