Yiziphi izimfuneko ezintsha inqubo engenawo umthofi ekhula ngokuya ngokuvuthwa ezifaka kuhhavini wokugeleza kabusha?

Sihlaziya kusukela ezicini ezilandelayo:

l Ungawuthola kanjani umehluko omncane wezinga lokushisa elingemuva

Njengoba iwindi lenqubo ye-solder-free soldering lincane, ukulawulwa komehluko wezinga lokushisa ehlangothini kubaluleke kakhulu.Izinga lokushisa ekufakweni kwe-reflow soldering ngokuvamile lithintwa izici ezine:

(1) Ukuhanjiswa komoya oshisayo

Amahhavini amanje ajwayelekile angenawo umthofu agelezayo wonke asebenzisa ukushisisa komoya oshisayo okungu-100%.Ekuthuthukisweni kwamahhavini agelezayo, izindlela zokushisisa nge-infrared nazo zivele.Kodwa-ke, ngenxa yokushisisa kwe-infrared, ukumuncwa kwe-infrared kanye nokubonakala kwezinto ezinemibala ehlukene kuhlukile futhi umphumela wethunzi ubangelwa ukuvinjwa kwamadivayisi asekuqaleni aseduze.Zombili lezi zimo zizodala umehluko wokushisa.I-solder engenawo umthofu isengozini yokugxumela ngaphandle kwefasitela lenqubo, ngakho-ke ubuchwepheshe bokushisa kwe-infrared buye baqedwa kancane kancane endleleni yokushisa ye-oven reflow.Ekufakweni kwe-lead-free soldering, umphumela wokudlulisa ukushisa udinga ukugcizelelwa.Ikakhulukazi kudivayisi yasekuqaleni enamandla amakhulu okushisa, uma ukudluliswa kokushisa okwanele kungatholakali, izinga lokushisa ngokusobala lizosala ngemuva kwalelo divayisi elinamandla amancane okushisa, okuholela ekuhlukeni kwezinga lokushisa elingemuva.Ake sibheke izindlela ezimbili zokudlulisa umoya oshisayo kuMdwebo 2 noFigure 3.

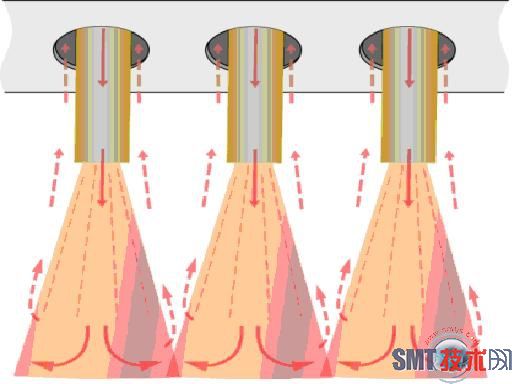

Umfanekiso 2 Indlela yokudlulisa umoya oshisayo 1

Umfanekiso 2 Indlela yokudlulisa umoya oshisayo 1

Umoya oshisayo kuMfanekiso 2 uphuma emigodini yepuleti lokushisa, futhi ukugeleza komoya oshisayo akunayo isiqondiso esicacile, kunalokho okungcolile, ngakho umphumela wokudlulisa ukushisa awumuhle.

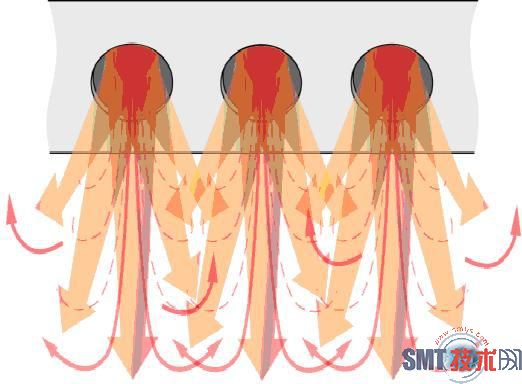

Idizayini yoMfanekiso 3 ifakwe imibhobho enamaphuzu amaningi omoya oshisayo, ngakho ukugeleza komoya oshisayo kugxilile futhi kunendlela ecacile.Umthelela wokudlulisa ukushisa walokhu kushisisa komoya oshisayo ukhuphuka cishe ngo-15%, futhi ukwanda komphumela wokudlulisa ukushisa kuzodlala indima enkulu ekwehliseni umehluko wokushisa osemaceleni wamadivayisi amakhulu namancane omthamo wokushisa.

Umklamo we-Figure 3 ungaphinda unciphise ukuphazamiseka komoya we-lateral ekushiseni kwebhodi lesifunda ngoba ukugeleza komoya oshisayo kunokuqondisa okucacile.Ukunciphisa umoya oseceleni akukwazi nje kuphela ukuvimbela izingxenye ezincane ezifana no-0201 ebhodini lesekethe ukuthi zingaphephuki, kodwa futhi kunciphisa ukugxambukela phakathi kwezindawo zokushisa ezihlukene.

(1) Ukulawula isivinini se-chain

Ukulawulwa kwejubane leketango kuzothinta umehluko wokushisa ongasemuva webhodi lesifunda.Ngokuvamile, ukunciphisa isivinini seketango kuzonikeza isikhathi sokushisisa esengeziwe samadivayisi anomthamo omkhulu wokushisa, ngaleyo ndlela kunciphise umehluko wokushisa osemaceleni.Kodwa emva kwakho konke, ukulungiselelwa kwejika lokushisa kwesithando somlilo kuncike ezidingweni ze-solder paste, ngakho-ke ukunciphisa okungenamkhawulo kwejubane leketanga akunangqondo ekukhiqizeni kwangempela.

(2) Isivinini somoya nokulawula ivolumu

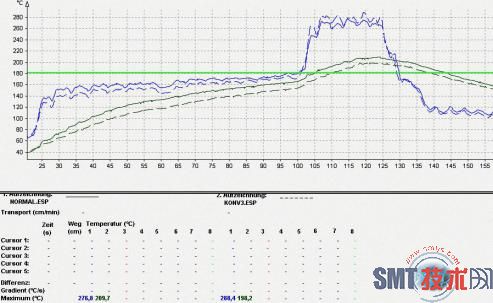

Senze ucwaningo olunjalo, sigcina ezinye izimo kuhhavini ogelezayo zingashintshiwe futhi sehlisa kuphela isivinini sabalandeli kuhhavini ogelezayo ngo-30%, futhi izinga lokushisa ebhodini lesifunda lizokwehla cishe ngamadigri ayi-10.Kungabonakala ukuthi ukulawulwa kwesivinini somoya kanye nevolumu yomoya kubalulekile ekulawuleni ukushisa kwesithando somlilo.

Isikhathi sokuthumela: Aug-11-2020