Geza kabushaihhaviniiwubuchwepheshe benqubo eyinhloko ku-SMT, ikhwalithi ye-reflow soldering iyisihluthulelo sokuthembeka, ithinta ngokuqondile ukuthembeka kokusebenza kanye nezinzuzo zezomnotho zemishini kagesi, futhi izinga lokushisela lincike endleleni yokushisela esetshenzisiwe, izinto zokushisela, ubuchwepheshe benqubo yokushisela kanye nokushisela. imishini.

YiniUmshini wokugcwalisa we-SMT?

I-Reflow soldering ingenye yezinqubo ezintathu ezibalulekile enqubweni yokubeka.I-Reflow soldering isetshenziselwa kakhulu ukuthengisa ibhodi lesifunda eliye lafakwa izingxenye, lithembele ekushiseni ukuze kuncibilike ukunamathisela kwe-solder ukwenza izingxenye ze-SMD namabhodi webhodi wesifunda ahlanganiswe ndawonye, bese ngokusebenzisa ukupholisa kwe-reflow soldering ukupholisa unamathisele we-solder qinisa izingxenye namaphedi ndawonye.Kodwa iningi lethu liyawuqonda umshini wokupakisha kabusha, okungukuthi, nge-reflow soldering yizingxenye zebhodi le-PCB welding eliqedile umshini, okwamanje uhla olubanzi kakhulu lwezinhlelo zokusebenza, ngokuyisisekelo iningi lemboni ye-elekthronikhi lizosetshenziswa, ukuqonda i-reflow soldering, okokuqala. ukuqonda inqubo ye-SMT, yebo, ngokwemibandela ye-layman ukushisela, kodwa inqubo yokushisela i-reflow soldering inikezwa izinga lokushisa elifanele, okungukuthi, ijika lokushisa lesithando somlilo.

Indima kahhavini ogelezayo

Indima yokugeleza kabusha izingxenye ze-chip ezifakwe ebhodini lesifunda ezithunyelwa ekamelweni lokugeleza kabusha, ngemva kokushisa okuphezulu okuzosetshenziselwa ukuthengisa izingxenye ze-chip ze-solder unamathisele emoyeni oshisayo oshisayo ukuze zenze inqubo yokuguqula izinga lokushisa lokugeleza lincibilike, ukuze izingxenye ze-chip namaphedi webhodi lesifunda kuhlangene, bese apholiswa ndawonye.

Izici zobuchwepheshe bokuthengisa kabusha

1. Izingxenye zingaphansi kokushaqeka okuncane kokushisa, kodwa ngezinye izikhathi zinikeza idivayisi ingcindezi enkulu yokushisa.

2. Kuphela ezingxenyeni ezidingekayo zokusetshenziswa kwe-solder unama, ingalawula inani lesicelo sokunamathisela i-solder, ingagwema ukukhiqizwa kweziphambeko ezifana nokuhlanganisa ibhuloho.

3. Ukungezwani okungaphezulu kwe-solder encibilikisiwe kungalungisa ukuphambuka okuncane kwendawo yokubeka yezingxenye.

4. Umthombo wokushisa wendawo wokushisa ungasetshenziswa ukuze izinqubo ezihlukene ze-soldering zisetshenziselwe ukuhlanganisa ku-substrate efanayo.

5. Ukungcola ngokuvamile akuxubene ku-solder.Uma usebenzisa i-solder paste, ukwakheka kwe-solder kungagcinwa ngendlela efanele.

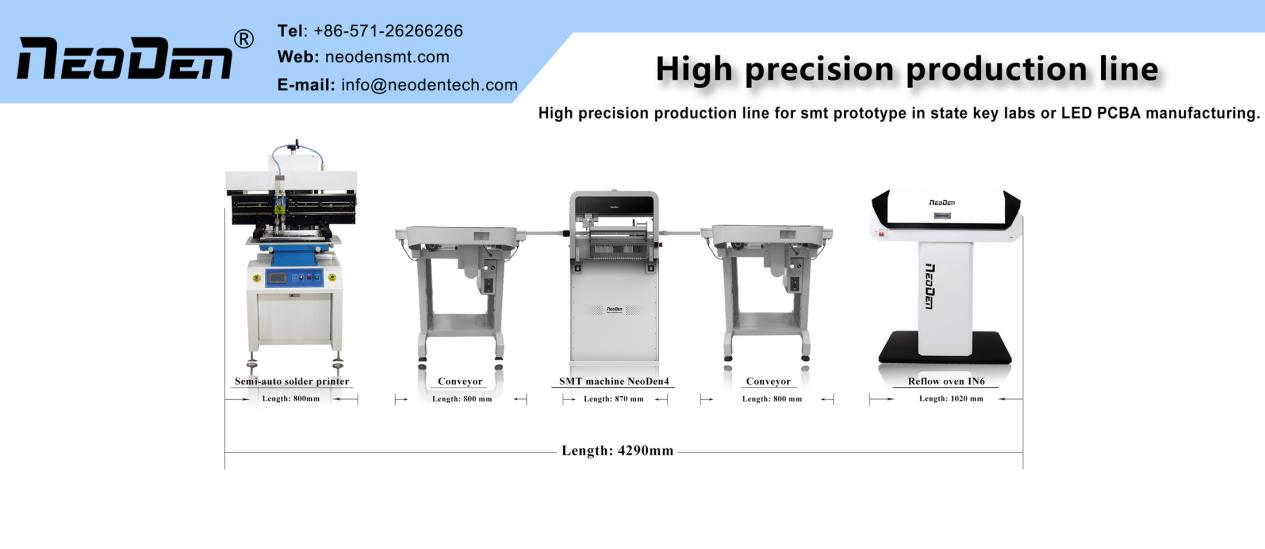

I-NeoDen IN6Geza kabusha izici ze-ovini

Ukulawula okuhlakaniphile okunenzwa yokushisa ezwelayo ephezulu, izinga lokushisa lingakwazi ukuzinza ngaphakathi kuka + 0.2 ℃.

Ukunikezwa kukagesi kwasekhaya, kulula futhi kuyasebenziseka.

I-NeoDen IN6 inikezela nge-reflow soldering esebenzayo yabakhiqizi be-PCB.

Imodeli entsha isidlulile isidingo se-heater ye-tubular, ehlinzeka ngokusabalaliswa kwezinga lokushisakulo lonke ihhavini lokugeleza kabusha.Ngokusoda ama-PCB ngisho naku-convection, zonke izingxenye zishiselwa ngesilinganiso esifanayo.

Izinga lokushisa lingalawulwa ngokunemba okukhulu—abasebenzisi bangakhomba ukushisa ngaphakathi kuka-0.2°C.

Idizayini isebenzisa ipuleti lokushisisa ingxubevange ye-aluminium enyusa ukusebenza kahle kwamandla kwesistimu.Isistimu yokuhlunga intuthu yangaphakathi ithuthukisa ukusebenza komkhiqizo futhi inciphisa okukhiphayo okuyingozi, nayo.

Isikhathi sokuthumela: Sep-07-2022