Ungayisebenzisa kanjani i-solder paste kunqubo ye-PCBA?

(1) Indlela elula yokwahlulela i-viscosity ye-solder paste: Gcoba unamathisele we-solder nge-spatula cishe imizuzu engu-2-5, thatha inhlama encane ye-solder nge-spatula, bese uvumela inhlama ye-solder iwe ngokwemvelo.I-viscosity iphakathi;uma i-solder paste ingasuki nhlobo, i-viscosity ye-solder paste iphezulu kakhulu;uma i-solder paste iqhubeka nokushesha ngokushesha, i-viscosity ye-solder paste incane kakhulu;

(2) Izimo zokugcinwa kwe-solder paste: faka efrijini ngendlela evalekile ezingeni lokushisa elingu-0°C kuya ku-10°C, futhi isikhathi sokugcina ngokuvamile siyizinyanga ezi-3 kuya kweziyisi-6;

(3) Ngemva kokuba i-solder paste isikhishiwe esiqandisini, kufanele ifudunyezwe endaweni yokushisa yasekamelweni amahora angaphezu kwama-4 ngaphambi kokuba isetshenziswe.Indlela yokushisisa ayikwazi ukusetshenziselwa ukubuyela ezingeni lokushisa;ngemva kokuba i-solder paste ifudumele, idinga ukugqugquzelwa (njengokuxuba nomshini, ukugqugquzela Amaminithi angu-1-2, ukugqugquzela ngesandla kudinga ukuqhutshwa ngaphezu kwemizuzu engu-2) ngaphambi kokusetshenziswa;

(4) Izinga lokushisa elizungezile lokuphrinta i-solder paste kufanele libe ngu-22℃~28℃, futhi umswakama kufanele ube ngaphansi kuka-65%;

(5) Ukuphrinta kwe-solder paste 1. Uma uphrinta unamathisele we-solder, kunconywa ukusebenzisa unamathisele we-solder ngokuqukethwe kwensimbi okungama-85% kuya ku-92% kanye nempilo yesevisi engaphezu kwamahora angu-4;

1. Uma uphrinta unamathisele we-solder, kunconywa ukusebenzisa unamathisele we-solder ngokuqukethwe kwensimbi okungama-85% kuya ku-92% kanye nempilo yesevisi engaphezu kwamahora angu-4;

2. Isivinini sokuphrinta Ngesikhathi sokunyathelisa, isivinini sokuhamba se-squeegee esifanekisweni sokuphrinta sibaluleke kakhulu, ngoba i-solder paste idinga isikhathi sokugoqa futhi igeleze emgodini wokufa.Umphumela uba ngcono uma i-solder paste igoqa ngokulinganayo ku-stencil.

3. Ukucindezela kokuphrinta Ukucindezela kokuphrinta kufanele kuhambisane nobulukhuni be-squeegee.Uma ingcindezi iphansi kakhulu, i-squeegee ngeke ihlanze ukunamathisela kwe-solder kusifanekiso.Uma ingcindezi inkulu kakhulu noma i-squeegee ithambile kakhulu, i-squeegee izocwila kusifanekiso.Gcoba unamathisele we-solder emgodini omkhulu.Ifomula yokuqina yengcindezi: Sebenzisa i-scraper kusifanekiso sensimbi.Ukuze uthole ingcindezi efanele, qala ngokufaka i-1 kg yengcindezi kuwo wonke ama-50 mm wobude be-scraper.Isibonelo, i-scraper engu-300 mm isebenzisa ingcindezi ye-6 kg ukunciphisa kancane kancane ingcindezi.Kuze kube yilapho i-solder paste iqala ukuhlala esifanekiso futhi ingaklwejwa ngokuhlanzekile, bese ukwandisa kancane kancane ukucindezela kuze kube yilapho unamathisele we-solder usanda kuklwejwa.Ngalesi sikhathi, ingcindezi ilungile.

4. Uhlelo lokuphatha inqubo kanye nemithethonqubo yenqubo Ukuze kuzuzwe imiphumela emihle yokuphrinta, kuyadingeka ukuthi ube nezinto ezifanele zokunamathisela i-solder (i-viscosity, okuqukethwe kwensimbi, ubukhulu bempushana obukhulu kanye nomsebenzi ophansi kakhulu we-flux), amathuluzi alungile (umshini wokunyathelisa, ithempulethi. kanye Nokuhlanganiswa kwe-scraper) kanye nenqubo efanele (ukuma okuhle, ukuhlanza nokusula).Ngokusho kwemikhiqizo ehlukene, setha imingcele yenqubo yokuphrinta ehambisanayo ohlelweni lokunyathelisa, njengokushisa okusebenzayo, ingcindezi yokusebenza, isivinini se-squeegee, isivinini sokudiliza, umjikelezo wokuhlanza isifanekiso esizenzakalelayo, njll. Ngesikhathi esifanayo, kuyadingeka ukwakha inqubo eqinile. uhlelo lokuphatha kanye nemithethonqubo yenqubo.

① Sebenzisa ukunamathisela kwe-solder phakathi nesikhathi sokuqinisekisa ngokuqinile ngokuhambisana nomkhiqizo obekiwe.I-solder paste kufanele igcinwe esiqandisini phakathi nezinsuku.Kufanele ibekwe ekamelweni lokushisa amahora angaphezu kwama-4 ngaphambi kokusetshenziswa, bese isivalo singavulwa ukuze sisetshenziswe.I-solder paste esetshenzisiwe kufanele ivalwe futhi igcinwe ngokwehlukana.Ukuthi ikhwalithi iyafaneleka yini.

② Ngaphambi kokukhiqiza, opharetha usebenzisa ummese okhethekile wensimbi engagqwali ukunyakazisa unama we-solder ukuze ulingane.

③ Ngemva kokuhlaziywa kokuphrinta kokuqala noma ukulungiswa kwemishini emsebenzini, umhloli we-solder unama ukujiya uzosetshenziswa ukukala ukujiya kokuphrinta kokunamathisela kwe-solder.Amaphuzu okuhlola akhethwa kumaphuzu angu-5 endaweni yokuhlola ebhodini eliphrintiwe, okuhlanganisa amaphuzu aphezulu naphansi, kwesokunxele nakwesokudla naphakathi, futhi abhale amanani.Ugqinsi lwe-solder paste lusukela ku- -10% kuya ku-+15% wogqinsi lwesifanekiso.

④ Phakathi nenqubo yokukhiqiza, ukuhlolwa okungu-100% kwenziwa kukhwalithi yokuphrinta ye-solder paste.Okuqukethwe okuyinhloko ukuthi iphethini yokunamathisela ye-solder iphelele yini, noma ngabe ukujiya kuyafana, nokuthi kukhona yini ukunamathisela kwe-solder.

⑤ Hlanza isifanekiso ngokwezidingo zenqubo ngemva kokuqedwa komsebenzi osemsebenzini.

⑥ Ngemuva kokuhlolwa kokuphrinta noma ukwehluleka ukuphrinta, ukunamathisela kwe-solder ebhodini eliphrintiwe kufanele kuhlanzwe kahle ngemishini yokuhlanza ye-ultrasonic futhi yomiswe, noma ihlanzwe ngotshwala negesi yokucindezela okuphezulu ukuvimbela ukunamathisela kwe-solder ebhodini ukuthi kungabangelwa uma kwenzeka. esetshenziswa futhi.Amabhola e-solder nezinye izenzakalo ngemva kokuphinda kufakwe i-solder

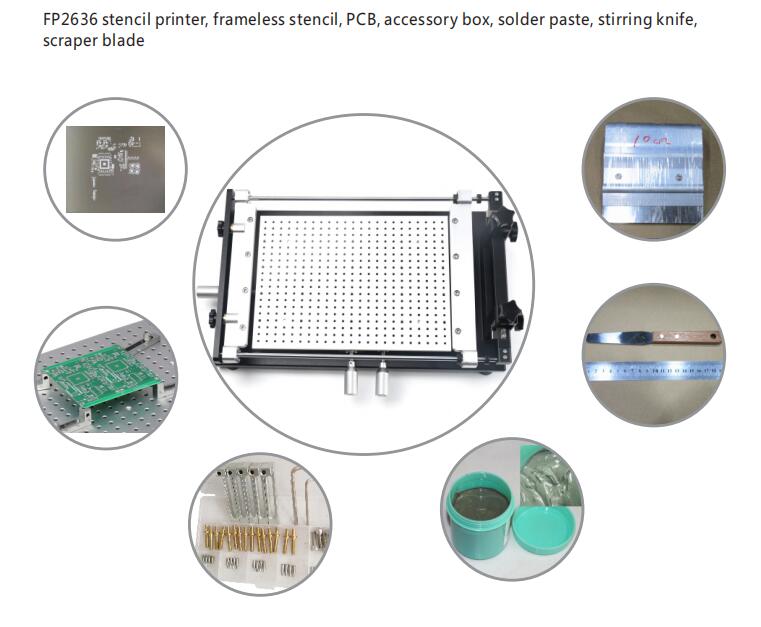

I-NeoDen ihlinzeka ngezixazululo ezigcwele zomugqa womhlangano we-SMT, okuhlanganisa i-oven reflow ye-SMT, umshini wokugcwalisa igagasi, umshini wokukhetha nendawo, iphrinta yokunamathisela i-solder, isilayishi se-PCB, isilayishi se-PCB, isikhuthazi se-chip, umshini we-SMT AOI, umshini we-SMT SPI, umshini we-SMT X-Ray, Imishini yomugqa we-SMT, Izisetshenziswa zokukhiqiza ze-PCB Izingxenye eziyisipele ze-SMT, njll.

I-Hangzhou NeoDen Technology Co., Ltd

Isikhathi sokuthumela: Jul-21-2020