I-oven ye-SMT egeleza kabushainqubo imfuneko kokubili ekupheleni izingxenye Chip solder welding ipuleti kufanele ezimele.Uma iphedi ixhunywe ngocingo oluphansi lwendawo enkulu, indlela yokuphamba ephambanweni kanye nendlela yokugandaya engu-45° kufanele ikhethwe.Intambo eholayo evela endaweni enkulu yocingo oluphansi noma ulayini wamandla mkhulu kuno-0.5mm, futhi ububanzi bungaphansi kuka-0.4mm;Intambo exhunywe kuphedi kanxande kufanele idonswe phakathi nendawo yohlangothi olude lwephedi ukuze kugwenywe i-engeli.

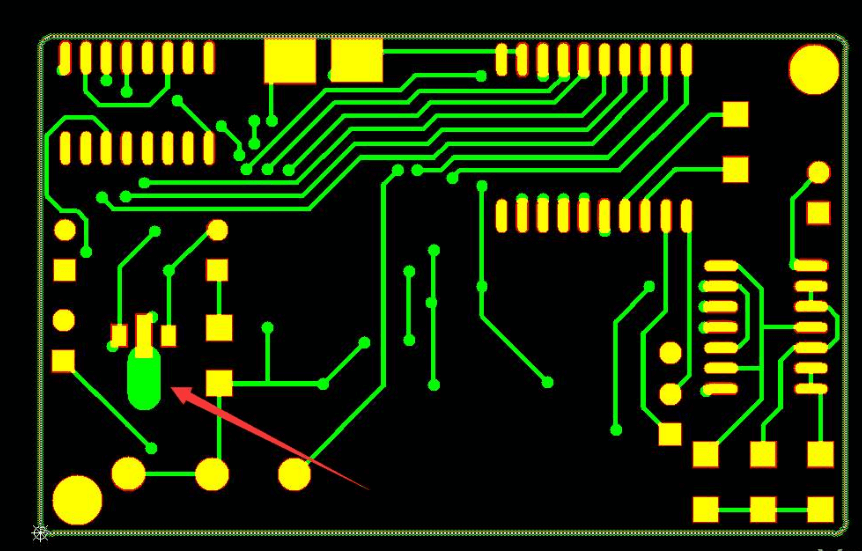

Bheka umfanekiso (a) ukuze uthole imininingwane.

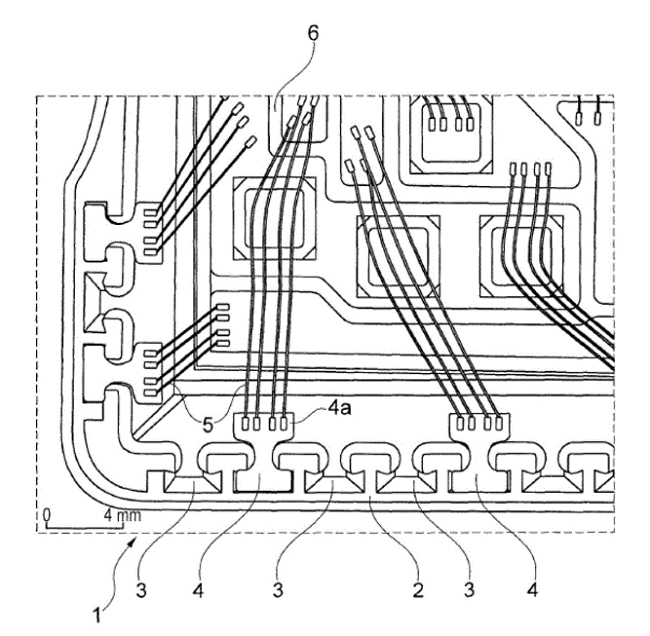

Izintambo eziphakathi kwamaphedi e-SMD nezintambo eziholayo zamaphedi zikhonjiswe emfanekisweni (b).Isithombe siwumdwebo wokuxhumana wephedi kanye nentambo ephrintiwe

Isiqondiso nesimo socingo oluphrintiwe:

(1) Intambo ephrintiwe yebhodi lesifunda kufanele ibe mfushane kakhulu, ngakho-ke, uma ungathatha okufushane kakhulu, ungahambi eziyinkimbinkimbi, ukulandela kungaba lula hhayi eziningi, short hhayi eside.Kuwusizo olukhulu ekulawuleni ikhwalithi yebhodi lesifunda le-PCB esigabeni sakamuva.

(2) Ukuqondiswa kocingo oluphrintiwe akufanele kube nokugoba okubukhali kanye ne-Angle ebukhali, futhi i-Angle yocingo oluphrintiwe akufanele ibe ngaphansi kuka-90 °.Lokhu kungenxa yokuthi kunzima ukugqwala ama-engeli amancane angaphakathi lapho wenza amapuleti.Emakhoneni angaphandle acijile kakhulu, i-foil ingaxebuka kalula noma igoqe.Indlela engcono kakhulu yokujika inguquko emnene, okungukuthi, ama-engeli angaphakathi nangaphandle ekhoneni ama-radians angcono kakhulu.

(3) Uma ucingo ludlula phakathi kwama-gaskets amabili futhi lungaxhunywanga nawo, kufanele lugcine ibanga eliphakeme nelilinganayo ukusuka kuwo;Ngokufanayo, amabanga phakathi kwezintambo kufanele afane futhi alingane futhi agcinwe phezulu.

Uma uxhuma izintambo phakathi kwamaphedi e-PCB, ububanzi bezintambo bungafana nobubanzi bamaphedi lapho ibanga phakathi kwesikhungo se-pads lingaphansi kobubanzi obungaphandle be-pads D;Uma ibanga eliphakathi phakathi kwamaphedi likhulu kuno-D, ububanzi bocingo kufanele buncishiswe.Uma kunamaphedi angaphezu kuka-3 kumaphedi, ibanga phakathi kwamakhondakta kufanele libe likhulu kuno-2D.

(4) Lapho uxhuma ama-conductor phakathi kwama-PCB pads, ububanzi bamakhondakta bungafana nobubanzi bamaphedi lapho ibanga phakathi kwesikhungo samaphedi lingaphansi kobubanzi obungaphandle D bamaphedi;Uma ibanga eliphakathi phakathi kwamaphedi likhulu kuno-D, ububanzi bocingo kufanele buncishiswe.Uma kunamaphedi angaphezu kwama-3 kumaphedi, ibanga phakathi kwamakhondakta kufanele libe likhulu kuno-2D.

(5) Ucwecwe lwethusi kufanele lugcinelwe ucingo oluvamile lwaphansi ngangokunokwenzeka.

Ukuze kwandiswe amandla e-peel we-liner, ulayini wokukhiqiza ongeyena oqhutshwayo unganikezwa.

Isikhathi sokuthumela: Jun-30-2021