Ukupakisha okuthuthukisiwe kungenye yezinto ezivelele zobuchwepheshe zenkathi 'Yokungaphezu kuka-Moore'.Njengoba ama-chips eba nzima kakhulu futhi ebiza kakhulu ukwenza i-miniaturise endaweni ngayinye yenqubo, onjiniyela bafaka ama-chips amaningi kumaphakheji athuthukile ukuze bangasakwazi ukuzabalaza ukuwashwabanisa.Lesi sihloko sinikeza isingeniso esifushane samagama angu-10 avame ukusetshenziswa kubuchwepheshe bokupakisha obuthuthukile.

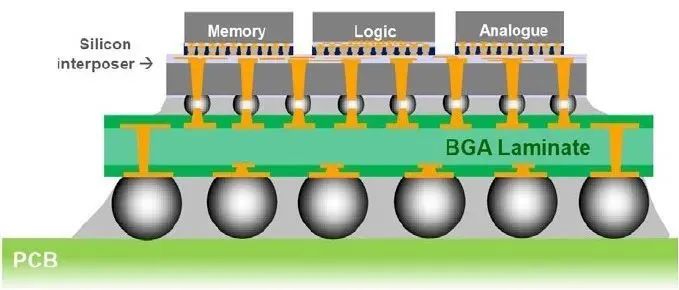

2.5D amaphakheji

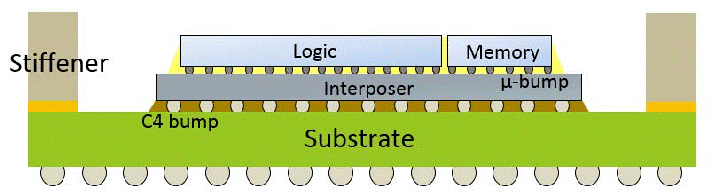

Iphakheji ye-2.5D iwukuthuthuka kobuchwepheshe bokupakisha bendabuko be-2D IC, okuvumela ulayini ocolekile nokusetshenziswa kwesikhala.Kuphakheji engu-2.5D, amafa angenalutho ayapakishwa noma abekwe ngapha nangapha phezu kwe-interposer layer ene-silicon nge-vias (TSVs).Isisekelo, noma isendlalelo se-interposer, sinikeza ukuxhumana phakathi kwama-chips.

Iphakheji ye-2.5D ngokuvamile isetshenziselwa ama-ASIC aphezulu, ama-FPGA, ama-GPU namakhyubhu enkumbulo.Ngo-2008 i-Xilinx yabona i-Xilinx ihlukanisa ama-FPGA ayo amakhulu abe ama-chips amane amancane anesivuno esiphezulu futhi ixhume lokhu kungqimba lwe-silicon interposer.Amaphakheji e-2.5D azalwa kanjalo futhi ekugcineni asetshenziswa kabanzi ekuhlanganisweni kwephrosesa ye-high bandwidth memory (HBM).

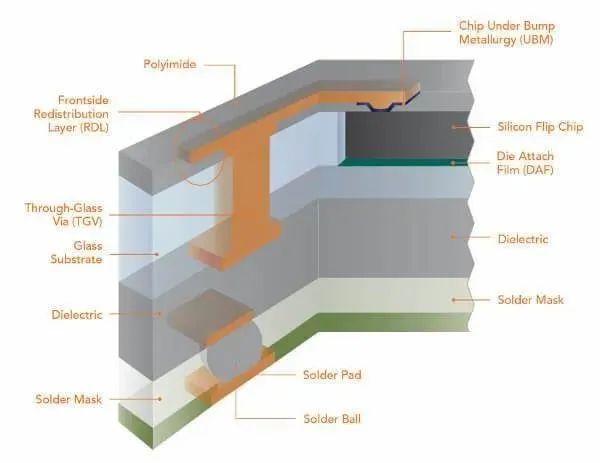

Umdwebo wephakheji ye-2.5D

Ukupakishwa kwe-3D

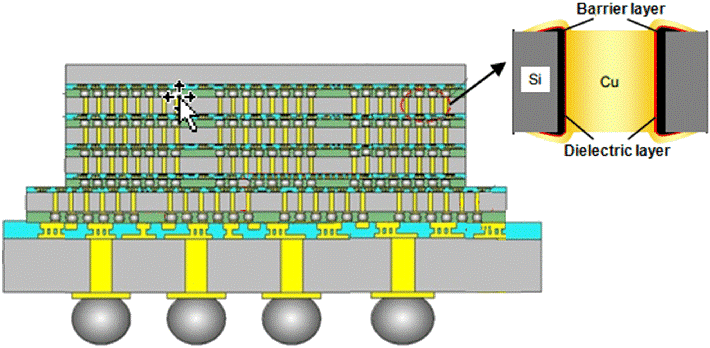

Kuphakheji ye-3D IC, i-logic die ipakishwa ndawonye noma inokufa kwesitoreji, okuqeda isidingo sokwakha ama-System-on-Chips (SoCs) amakhulu.I-die ixhunywe enye nenye ngesendlalelo se-interposer esisebenzayo, kuyilapho amaphakheji e-2.5D IC esebenzisa ama-conductive bumps noma ama-TSV ukuze abeke izingxenye kungqimba lwe-interposer, amaphakheji e-3D IC axhuma izendlalelo eziningi zamawafa e-silicon ezingxenyeni ezisebenzisa ama-TSV.

Ubuchwepheshe be-TSV buwukhiye obuvumela ubuchwepheshe kuwo womabili amaphakheji e-2.5D kanye ne-3D IC, futhi imboni ye-semiconductor ibisebenzisa ubuchwepheshe be-HBM ukukhiqiza ama-chip e-DRAM kumaphakheji e-3D IC.

Ukubuka okuphambene kwephakheji ye-3D kubonisa ukuthi ukuxhumana okuqondile phakathi kwama-silicon chips kufinyelelwa ngama-TSV e-metallic copper.

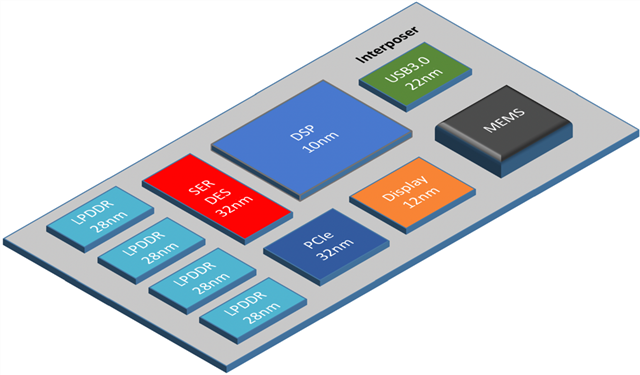

I-Chiplet

Ama-Chiplets angolunye uhlobo lokupakishwa kwe-3D IC olunika amandla ukuhlanganiswa okuhlukile kwe-CMOS nezingxenye ezingezona eze-CMOS.Ngamanye amazwi, angama-SoCs amancane, abizwa nangokuthi ama-chiplets, kunokuba ama-SoC amakhulu ephaketheni.

Ukwephula i-SoC enkulu ibe ama-chips amancane, amancane kunikeza isivuno esiphezulu nezindleko eziphansi kunokufa okukodwa okungenalutho.ama-chiplets avumela abaklami ukuthi basebenzise i-IP ehlukahlukene ngaphandle kokucabangela ukuthi iyiphi i-node yenqubo okufanele isetshenziswe nokuthi ibuphi ubuchwepheshe okufanele busetshenziswe ukuyikhiqiza.Bangasebenzisa inhlobonhlobo yezinto zokwakha, okuhlanganisa i-silicon, ingilazi namalayini ukuze benze i-chip.

Amasistimu asuselwa ku-Chiplet akhiwe ama-Chiplets amaningi kusendlalelo esimaphakathi

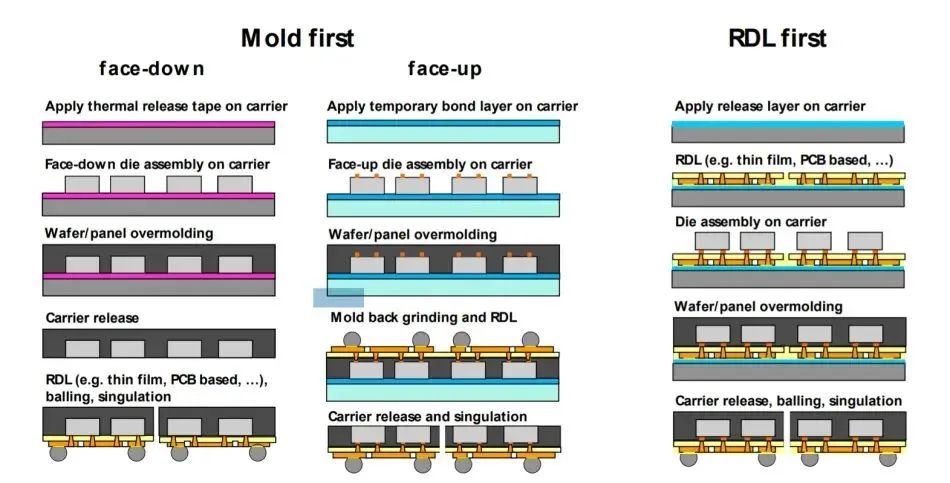

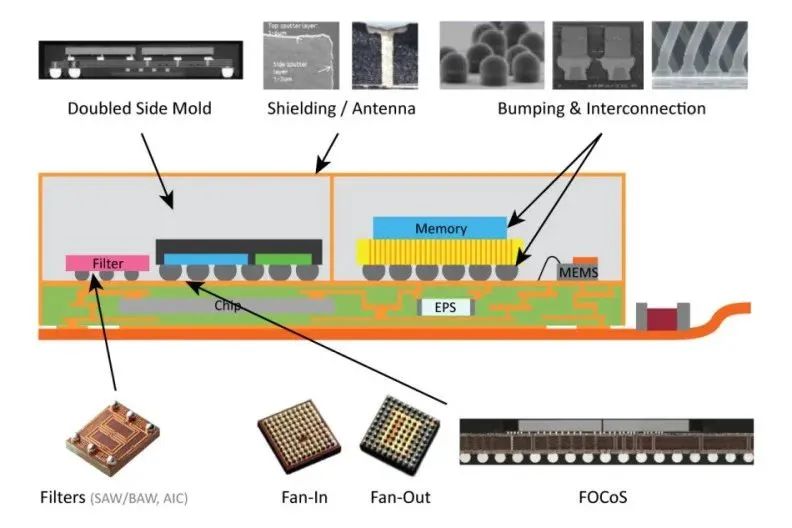

Amaphakheji we-Fan Out

Kuphakheji ye-Fan Out, "uxhumano" lufenelwa ngaphandle kwe-chip ukuze kuhlinzekwe i-I/O yangaphandle eyengeziwe.Isebenzisa i-epoxy molding material (EMC) eshumekwe ngokugcwele ku-die, isusa isidingo sezinqubo ezifana nokugoqa i-wafer, ukuguquguquka, ukukhweza i-flip-chip, ukuhlanza, ukufafaza okuphansi kanye nokwelapha.Ngakho-ke, asikho isendlalelo esiphakathi esidingekayo noma, okwenza ukuhlanganisa okungafani kube lula kakhulu.

Ubuchwepheshe be-Fan-out bunikeza iphakheji elincane eline-I/O eningi kunezinye izinhlobo zephakeji, futhi ngo-2016 kwaba inkanyezi yobuchwepheshe lapho i-Apple yakwazi ukusebenzisa ubuchwepheshe bokupakisha be-TSMC ukuhlanganisa iphrosesa yayo yesicelo se-16nm kanye ne-DRAM yeselula ibe iphakheji elilodwa le-iPhone. 7.

Ukupakisha kwabalandeli

I-Fan-Out Wafer Level Packaging (FOWLP)

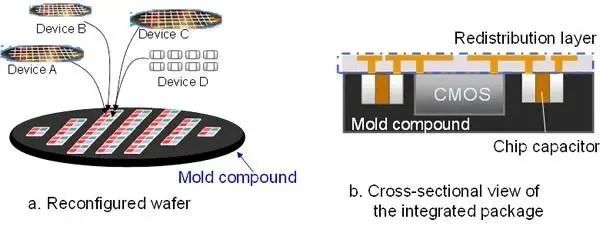

Ubuchwepheshe be-FOWLP buwukuthuthukiswa kokupakishwa kwe-wafer-level (WLP) okunikeza ukuxhumana kwangaphandle okwengeziwe kwama-silicon chips.Kubandakanya ukushumeka i-chip kwinto yokubumba ye-epoxy bese kwakhiwe ungqimba oluphezulu lokusabalalisa kabusha ukuminyana (i-RDL) endaweni eyi-wafer bese usebenzisa amabhola e-solder ukuze akhe iwafa ehlanganiswe kabusha.

I-FOWLP ihlinzeka ngenani elikhulu lokuxhumana phakathi kwephakheji nebhodi lesicelo, futhi ngenxa yokuthi i-substrate inkulu kunokufa, i-die pitch empeleni ikhululekile kakhulu.

Isibonelo sephakheji ye-FOWLP

Ukuhlanganiswa okungafani

Ukuhlanganiswa kwezingxenye ezihlukene ezikhiqizwe ngokuhlukene kuma-assembly asezingeni eliphezulu kungathuthukisa ukusebenza futhi kuthuthukise izici zokusebenza, ngakho-ke abakhiqizi bezingxenye ze-semiconductor bayakwazi ukuhlanganisa izingxenye ezisebenzayo nenqubo egelezayo ehlukene ibe umhlangano owodwa.

Ukuhlanganiswa kwe-Heterogeneous kufana ne-system-in-package (SiP), kodwa esikhundleni sokuhlanganisa ukufa okuningi okungenalutho ku-substrate eyodwa, kuhlanganisa ama-IP amaningi ngendlela yama-Chiplets ku-substrate eyodwa.Umqondo oyisisekelo wokuhlanganiswa okungafani ukuhlanganisa izingxenye eziningi ezinemisebenzi ehlukene kuphakheji efanayo.

Amanye amabhlogo wokwakha wezobuchwepheshe ekuhlanganiseni okuhlukahlukene

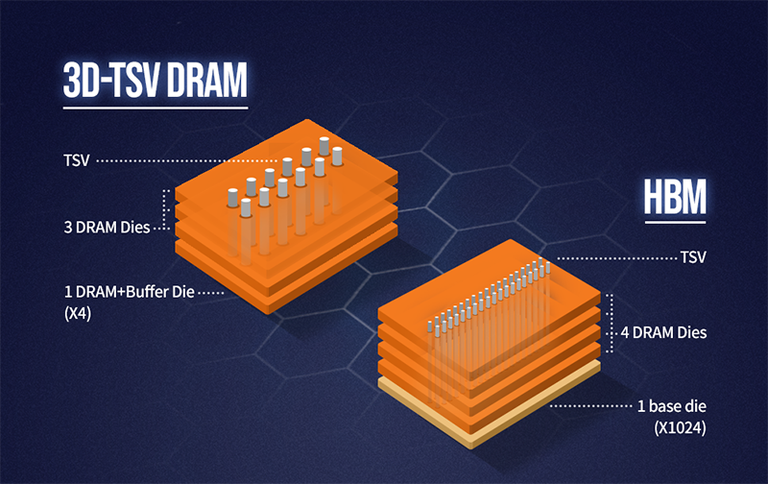

HBM

I-HBM iwubuchwepheshe obujwayelekile bokugcina isitaki obuhlinzeka ngamashaneli aphezulu omkhawulokudonsa wedatha ngaphakathi kwesitaki naphakathi kwenkumbulo nezinto ezinengqondo.Inkumbulo yamaphakheji e-HBM iyafa futhi iwaxhume ndawonye nge-TSV ukuze kwakhe i-I/O eyengeziwe kanye nomkhawulokudonsa.

I-HBM iyindinganiso ye-JEDEC ehlanganisa ngokuqondile izendlalelo eziningi zezingxenye ze-DRAM ngaphakathi kwephakheji, kanye namaphrosesa wohlelo lokusebenza, ama-GPU nama-SoCs.I-HBM isetshenziswa ngokuyinhloko njengephakheji ye-2.5D yamaseva asezingeni eliphezulu nama-chips enethiwekhi.Ukukhishwa kwe-HBM2 manje kusingatha umthamo kanye nemikhawulo yezinga lewashi lokukhishwa kokuqala kwe-HBM.

Amaphakheji we-HBM

Isendlalelo Esimaphakathi

Isendlalelo se-interposer ipayipi lapho amasiginali kagesi adluliswa khona ukusuka ku-multi-chip bare die noma ibhodi kuphakheji.Kuwukuxhumana kukagesi phakathi kwamasokhethi noma izixhumi, okuvumela amasiginali ukuthi asakazwe kude futhi axhunywe kwamanye amasokhethi ebhodini.

Isendlalelo se-interposer singenziwa nge-silicon nezinto eziphilayo futhi sisebenza njengebhuloho phakathi kwe-multi-die die nebhodi.Izendlalelo ze-Silicon interposer ziwubuchwepheshe obufakazelwe obunobukhulu be-I/O bephimbo eliphezulu namandla okwakheka kwe-TSV futhi budlala indima ebalulekile ekufakweni kwe-chip ye-2.5D ne-3D IC.

Ukuqaliswa okujwayelekile kwesendlalelo esimaphakathi esihlukanisayo

Isendlalelo sokusabalalisa kabusha

Isendlalelo sokusabalalisa kabusha siqukethe izixhumanisi zethusi noma ukuqondanisa okuvumela ukuxhumana kukagesi phakathi kwezingxenye ezihlukahlukene zephakheji.Ungqimba lwensimbi yensimbi noma ye-polymeric ye-dielectric engapakishwa kuphakheji ngokufa okungenalutho, ngaleyo ndlela kuncishiswe isikhala se-I/O sama-chipsets amakhulu.Izendlalelo zokusabalalisa kabusha zibe yingxenye ebalulekile yezixazululo zephakheji ye-2.5D ne-3D, okuvumela ama-chips kuzo ukuthi axhumane kusetshenziswa izendlalelo ezimaphakathi.

Amaphakheji ahlanganisiwe asebenzisa izendlalelo zokusabalalisa kabusha

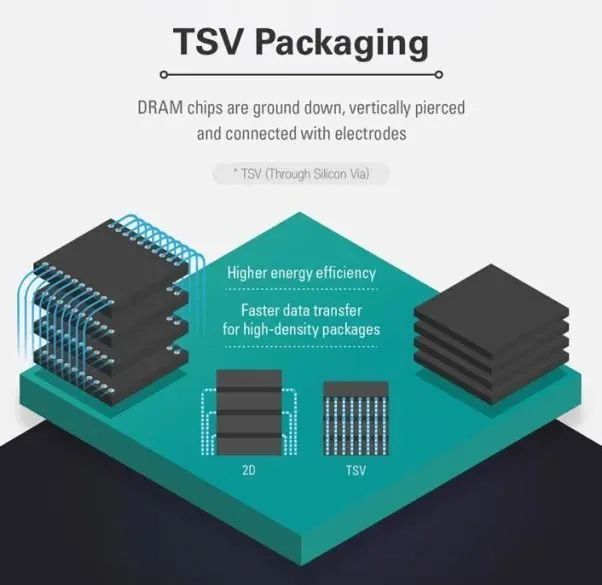

I-TSV

I-TSV iwubuchwepheshe bokuqalisa obubalulekile bezisombululo zokupakisha ze-2.5D ne-3D futhi iyiwafa egcwele ithusi ehlinzeka ngoxhumano oluqondile nge-silicon wafer die.Igijima kuyo yonke i-die ukuze inikeze uxhumano lukagesi, yenza indlela emfushane ukusuka kolunye uhlangothi lwefa kuya kolunye.

Izimbobo noma ama-vias aqoshwe ekujuleni okuthile ukusuka ohlangothini olungaphambili lwe-wafer, ebese ivalwa bese igcwaliswa ngokufaka into yokuqhuba (imvamisa ithusi).Uma i-chip seyakhiwe, iyancishiswa kusukela ohlangothini olungemuva lwewafa ukuze kuvezwe i-vias nensimbi efakwe ngemuva kwewafa ukuze kuqedelwe ukuxhuma kwe-TSV.

Isikhathi sokuthumela: Jul-07-2023