Ukucutshungulwa kwe-chip ye-SMT kancane kancane kuya ekuminyaneni okuphezulu, ukuthuthukiswa komklamo omuhle wephimbo, ukuhlukana okuncane kokuklanywa kwezingxenye, kudingeka kucatshangelwe ulwazi lomkhiqizi we-SMT kanye nokuphelela kwenqubo.Idizayini yesikhala esincane sezingxenye, ngaphezu kokuqinisekisa ibanga lokuphepha phakathi kwamaphedi e-SMT, kufanele futhi icabangele ukugcinwa kwezingxenye.

Qinisekisa isikhala esiphephile lapho ubeka izingxenye

1. Ibanga lokuphepha lihlobene nokuvuleka kwe-stencil, ukuvulwa kwe-stencil kukhulu kakhulu, ukushuba kwe-stencil kukhulu kakhulu, ukungezwani kwe-stencil akwanele ukuguqulwa kwe-stencil, kuzoba ne-welding bias, okuholela ezingxenyeni ngisho ne-tin short circuit.

2. Emsebenzini ofana ne-hand soldering, i-solder ekhethiwe, i-tooling, i-rework, ukuhlola, ukuhlola, ukuhlanganisa kanye nezinye indawo yokusebenza, ibanga liyadingeka.

3. Usayizi wesikhala phakathi kwamadivayisi we-chip uhlobene nomklamo wephedi, uma iphedi ingasuki ngaphandle kwephakheji yengxenye, unamathisele we-solder uzonyathela phezulu ekugcineni kwengxenye yohlangothi lwe-solder, okuya kuba mncane ingxenye. kuwukuhlanganisa ngisho isifunda esifushane.

4. Inani lokuphepha lesikhala phakathi kwezingxenye alilona inani eliphelele, njengoba imishini yokukhiqiza ayifani, kukhona umehluko emandleni okwenza umhlangano, inani lokuphepha lingachazwa njengobunzima, okungenzeka, ukuphepha.

Amaphutha esakhiwo sengxenye engenangqondo

Izingxenye ku-PCB ekuhleleni okulungile kokufakwa, kuyingxenye ebaluleke kakhulu yokunciphisa ukukhubazeka kokushisela, ukuhlelwa kwengxenye, kufanele kube kude ngangokunokwenzeka ekuphambukeni kwendawo enkulu nezindawo zokucindezeleka okukhulu, ukusatshalaliswa kufanele kufane njengoba kungenzeka, ikakhulukazi izingxenye ezinomthamo omkhulu oshisayo, kufanele zizame ukugwema ukusetshenziswa kwe-PCB enkulu kakhulu ukuvimbela ukungqubuzana, ukwakheka okungekuhle kwesakhiwo kuzothinta ngqo ukuhlangana kwe-PCBA nokuthembeka.

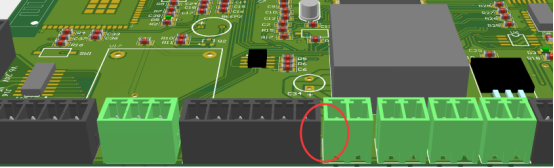

1. Ibanga lesixhumi liseduze kakhulu

Izixhumi ngokuvamile ziyizingxenye eziphakeme, ekuhlelweni kwebanga lesikhathi eliseduze kakhulu, elihlanganiswe eduze kwesinye ngemva kokuba isikhala sisincane kakhulu, asinakho ukusebenza kabusha.

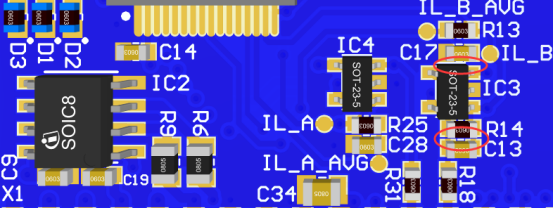

2. Ibanga lamadivayisi ahlukene

Ku-SMT, ngenxa yesikhala esincane samadivayisi athambekele ekwenzeni amabhuloho, amadivaysi ahlukene ahlanganisa ngaphezu kwalokho okwenzeka ku-0.5mm nangaphansi kwesikhala, ngenxa yesikhala sawo esincane, ngakho-ke ukwakheka kwesifanekiso se-stencil noma ukuphrinta okushiyelwe kancane kulula kakhulu ukukhiqiza. ibhuloho, futhi ukuhlukaniswa kwezingxenye kuncane kakhulu, kunengozi yesifunda esifushane.

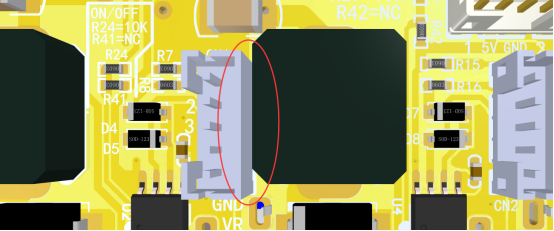

3. Ukuhlanganiswa kwezingxenye ezimbili ezinkulu

Ugqinsi lwezingxenye ezimbili ezisondelene eduze, luzobangela umshini wokubeka ekubekweni kwengxenye yesibili, ukuthinta okungaphambili kuthunyelwe izingxenye, ukutholwa kwengozi ebangelwa umshini ukucisha ngokuzenzakalelayo.

4. Izingxenye ezincane ngaphansi kwezingxenye ezinkulu

Izingxenye ezinkulu ngaphansi kokubekwa kwezingxenye ezincane, zizobangela imiphumela yokungakwazi ukulungisa, isibonelo, ithubhu yedijithali ngaphansi kwe-resistor, izobangela ubunzima bokulungisa, ukulungisa kufanele kuqala kususe ithubhu yedijithali ukulungisa, futhi kungase kubangele ukulimala kwe-tube yedijithali. .

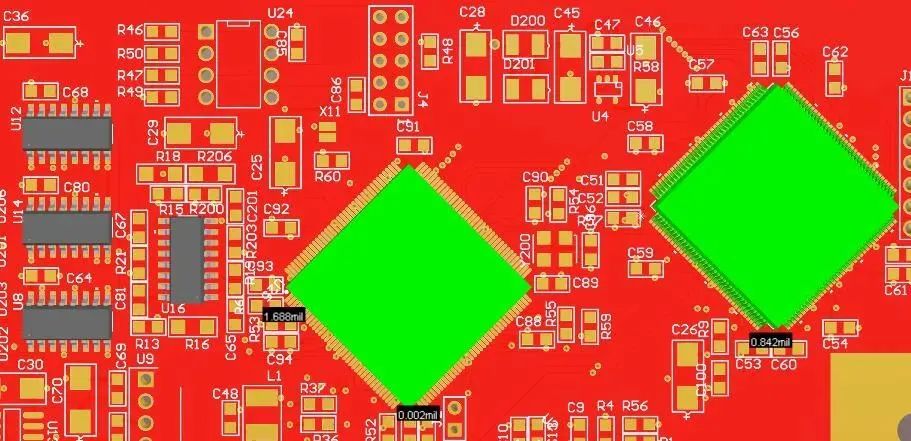

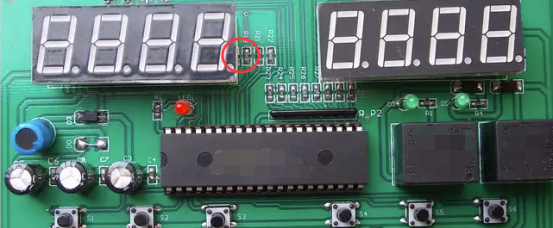

Ikesi yesifunda esifushane esibangelwa ibanga elisondele kakhulu phakathi kwezingxenye

>> Incazelo Yenkinga

Umkhiqizo osekukhiqizweni kwe-chip ye-SMT, uthole ukuthi ibanga le-capacitor C117 ne-C118 lingaphansi kuka-0.25mm, ukukhiqizwa kwe-chip ye-SMT kunento yesekethe ye-tin emfushane.

>> Umthelela Wenkinga

Kubangele isifunda esifushane kumkhiqizo futhi kuthinte umsebenzi womkhiqizo;ukuyithuthukisa, sidinga ukushintsha ibhodi futhi sandise ibanga le-capacitor, eliphinde lithinte umjikelezo wokuthuthukiswa komkhiqizo.

>> Inkinga Isandiso

Uma ukuhlukana kungasondeli ikakhulukazi, futhi isifunda esifushane singabonakali, kuzoba yingozi yokuphepha, futhi umkhiqizo uzosetshenziswa umsebenzisi onezinkinga zesekethe emfushane, okubangela ukulahlekelwa okungenakucatshangwa.

Isikhathi sokuthumela: Apr-18-2023