1) I-stencil ye-Electroforming

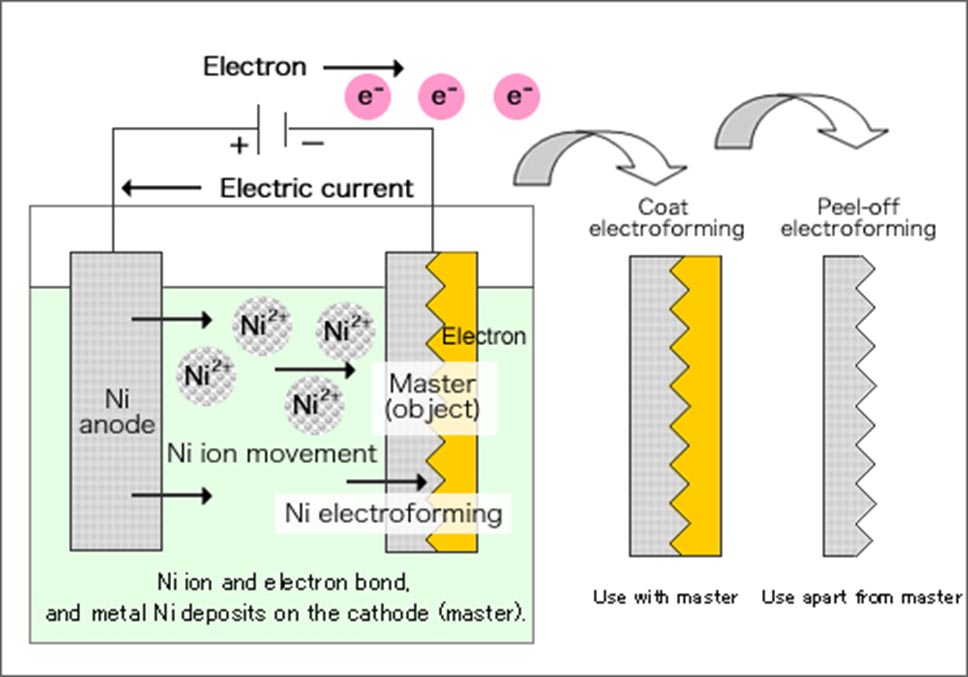

Umgomo wokukhiqiza we-stencil ene-electroformed: isifanekiso esine-electroformed senziwa ngokuphrinta impahla ye-photoresist ku-conductive metal base plate, bese ngokusebenzisa isikhunta esifihlakele kanye nokuchayeka kwe-ultraviolet, bese isifanekiso esincanyana senziwe nge-electroform oketshezini lwe-electroforming.Eqinisweni, i-electroforming ifana ne-electroplating, ngaphandle kokuthi ishidi le-nickel ngemva kwe-electroforming lingasuswa epuleti eliphansi ukuze lenze i-stencil.

I-stencil ye-Electroforming inezici ezilandelayo: akukho ukucindezeleka ngaphakathi kweshidi lensimbi, udonga lwembobo lubushelelezi kakhulu, i-stencil ingaba yinoma yikuphi ukushuba (ngaphakathi kwe-0.2mm, elawulwa yisikhathi se-electroforming), ukungahambi kahle ukuthi izindleko ziphezulu.Isibalo esilandelayo siwukuqhathaniswa kwe-laser steel mesh nodonga lwensimbi ene-electroformed.Udonga lwembobo ebushelelezi lwe-electroformed steel mesh lunomphumela ongcono wokudiliza ngemva kokuphrinta, ukuze isilinganiso sokuvula sibe phansi sibe ngu-0.5.

2) I-stencil yesitebhisi

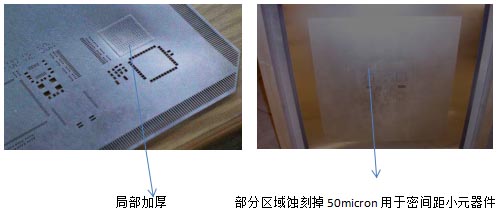

Imeshi yensimbi enezinyathelo ingagqitshwa endaweni noma incitshwe.Ingxenye egqinsiwe ngokwengxenye isetshenziselwa ukuphrinta amaphedi e-solder adinga inani elikhulu lokunamathisela kwe-solder, futhi ingxenye eqinisiwe ibonakala nge-electroforming, futhi izindleko ziphakeme.Ukunciphisa kufezwa ngokufakwa kwamakhemikhali.Ingxenye encishisiwe isetshenziselwa ukuphrinta amaphedi wezingxenye ezincane, okwenza umphumela wokudiliza ube ngcono.Abasebenzisi abangazweli kakhulu izindleko batuswa ukuthi basebenzise i-chemical etching, eshibhile.

3) I-Nano Ultra Coating

Ukugqoka noma ukuhlanganisa ungqimba lwe-nano-coating ebusweni bensimbi yensimbi, i-nano-coating yenza udonga lwembobo luxoshe ukunamathisela kwe-solder, ngakho-ke umphumela wokudiliza ungcono, futhi ukuzinza kwevolumu yokuphrinta kwe-solder paste kuyavumelana.Ngale ndlela, ikhwalithi yokunyathelisa iqinisekisiwe kakhulu, futhi inani lokuhlanza nokusula insimbi yensimbi nalo lingancishiswa.Njengamanje, izinqubo eziningi zasekhaya zisebenzisa kuphela ungqimba lwe-nano-coating, futhi umphumela uba buthakathaka ngemva kwenani elithile lokunyathelisa.Kukhona ama-nano-coatings afakwe ngokuqondile ku-mesh yensimbi, enomphumela ongcono nokuqina, futhi-ke izindleko ziphakeme.

3. Inqubo yokubumba ye-solder yokunamathisela kabili.

1) Ukuphrinta/Ukuphrinta

Imishini emibili yokuphrinta isetshenziselwa ukuphrinta nokwenza i-solder paste.Eyokuqala isebenzisa i-stencil evamile ukuze iphrinte amaphedi ezingxenye ezincane ezinezwi elihle, kanti eyesibili isebenzisa i-stencil ye-3D noma i-stencil yesinyathelo ukuze uphrinte amaphedi ezingxenye ezinkulu.

Le ndlela idinga imishini yokunyathelisa emibili, futhi izindleko ze-stencil nazo ziphezulu.Uma kusetshenziswa i-stencil ye-3D, i-comb scraper iyadingeka, okwandisa izindleko kanye nokusebenza kahle kokukhiqiza nakho kuphansi.

2) Ukuphrinta/kufafaza ithini

Iphrinta yokunamathisela ye-solder yokuqala iphrinta amaphedi ezingxenye ezincane ezisondelene, futhi iphrinta ye-inkjet yesibili iphrinta amaphedi ezingxenye ezinkulu.Ngale ndlela, umphumela wokubumba we-solder unamathisele muhle, kepha izindleko ziphezulu futhi ukusebenza kahle kuphansi (kuye ngokuthi inani lamaphedi engxenye enkulu).

Abasebenzisi bangakhetha ukusebenzisa izixazululo ezimbalwa ezingenhla ngokuya ngesimo sabo.Ngokuphathelene nezindleko nokusebenza kahle kokukhiqiza, ukunciphisa ukujiya kwe-stencil, kusetshenziswa ama-stencil wesilinganiso sendawo yokuvula edingekayo ephansi, kanye nama-stencil esinyathelo yizinqumo ezifanele kakhulu;abasebenzisi abanokukhishwa okuphansi, izimfuneko zekhwalithi ephezulu, nabasebenzisi abangenandaba nezindleko bangakhetha Uhlelo lokuphrinta/lokuphrinta kwejethi.

Isikhathi sokuthumela: Aug-07-2020