Ukuze siqonde izinselele ezilethwa izingxenye ezincane ekuphrinteni kokunamathisela kwe-solder, kufanele siqale siqonde isilinganiso sendawo yokuphrinta kwe-stencil (I-Area Ratio).

Ukuphrinta kwe-solder paste yama-miniaturized pads, i-pad encane kanye nokuvuleka kwe-stencil, kunzima kakhulu ukuthi unamathisele we-solder uhlukanise nodonga lwembobo ye-stencil. ngereferensi:

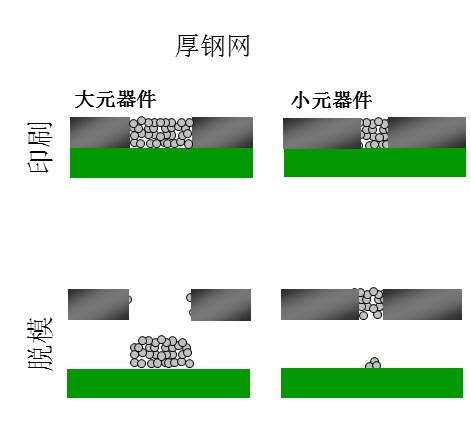

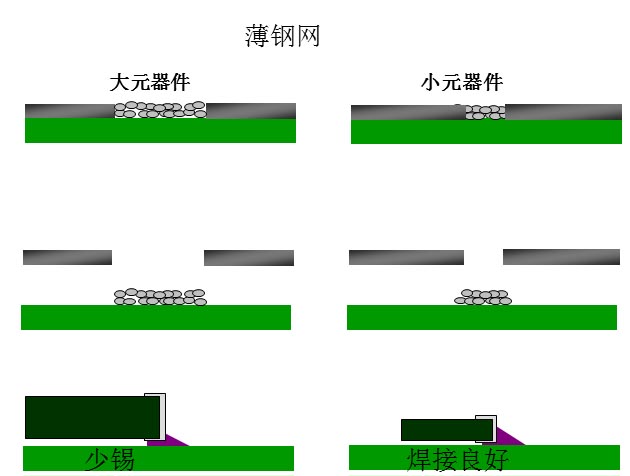

- Isixazululo esiqondile kakhulu ukunciphisa ubukhulu bensimbi yensimbi futhi ukwandise isilinganiso sendawo yokuvuleka.Njengoba kuboniswe emfanekisweni ongezansi, ngemva kokusebenzisa i-mesh yensimbi encane, i-soldering ye-pads yezingxenye ezincane kuhle.Uma i-substrate ekhiqizwayo ingenazo izingxenye zosayizi omkhulu, khona-ke lesi yisixazululo esilula nesisebenza kakhulu.Kodwa uma kunezingxenye ezinkulu ku-substrate, izingxenye ezinkulu zizothengiswa kabi ngenxa yenani elincane le-tin.Ngakho-ke uma kuyingxubevange ephezulu enezingxenye ezinkulu, sidinga ezinye izixazululo ezibalwe ngezansi.

- Sebenzisa ubuchwepheshe obusha bensimbi yensimbi ukuze unciphise imfuneko yesilinganiso sokuvuleka ku-stencil.

1) FG (Fine Grain) istencil sensimbi

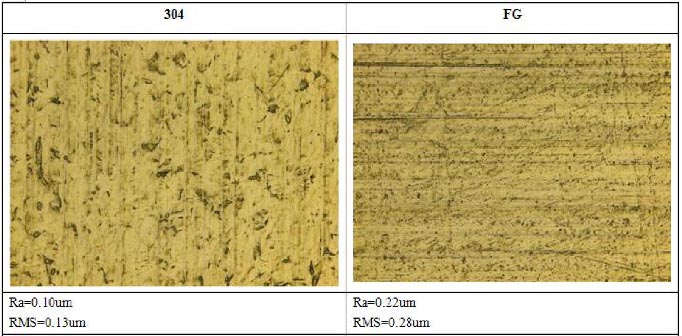

Ishidi lensimbi le-FG liqukethe uhlobo lwe-niobium element, engacolisa okusanhlamvu futhi inciphise ukuzwela ukushisa ngokweqile kanye nokufutheka kwensimbi, futhi ithuthukise amandla.Imbobo yodonga lweshidi lensimbi le-laser-cut FG lihlanzekile futhi libushelelezi kunalelo leshidi lensimbi elijwayelekile elingu-304, elilungele ukubhidlizwa.Isilinganiso sendawo yokuvula yensimbi yensimbi eyenziwe ngeshidi lensimbi ye-FG ingaba ngaphansi kuka-0.65.Uma kuqhathaniswa ne-304 steel mesh enesilinganiso esifanayo sokuvula, i-FG steel mesh ingenziwa ijiyile kancane kune-304 mesh yensimbi, ngaleyo ndlela kuncishiswe ubungozi bethini elincane lezingxenye ezinkulu .

Isikhathi sokuthumela: Aug-05-2020