Njengamanje, abakhiqizi abaningi bemikhiqizo ye-elekthronikhi ethuthukisiwe ekhaya nakwamanye amazwe bahlongoze umqondo omusha wokulungiswa kwemishini “ukugcinwa okuvumelanayo” ukuze kuqhutshekwe nokunciphisa umthelela wokulungiswa ekusebenzeni kahle kokukhiqiza.Okungukuthi, lapho i-ovini yokugeleza kabusha isebenza ngokugcwele, uhlelo lokushintshwa kwesondlo oluzenzakalelayo lwemishini lusetshenziselwa ukwenza ukugcinwa nokugcinwa kwehhavini eligelezayo livumelane ngokuphelele nokukhiqiza.Lo mklamo uwushiya ngokuphelele umqondo wasekuqaleni “wokulungisa ukuvala shaqa,” futhi uthuthukisa ngokwengeziwe ukusebenza kahle kokukhiqiza kwawo wonke ulayini we-SMT.

Izimfuneko zokuqaliswa kwenqubo:

Izisetshenziswa zekhwalithi ephezulu zingakhiqiza izinzuzo kuphela ngokusetshenziswa kochwepheshe.Njengamanje, izinkinga eziningi ezihlangatshezwana neningi labakhiqizi ekukhiqizeni i-solder-free soldering azizange zivele emishini ngokwayo, kodwa zidinga ukuxazululwa ngokulungiswa kwenqubo.

l Ukusetha ijika lokushisa kwesithando somlilo

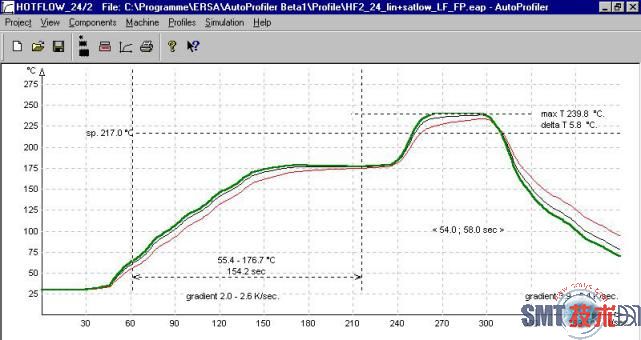

Ngenxa yokuthi iwindi lenqubo ye-solder-free soldering lincane kakhulu, futhi kufanele siqinisekise ukuthi wonke amalunga e-solder angaphakathi kwefasitela lenqubo ngesikhathi esifanayo endaweni yokugeleza kabusha, ngakho-ke, ijika lokugeleza elingenalutho lokuhola livame ukusetha "i-flat top" ( bheka Umfanekiso 9).

Umfanekiso 9 "I-Flat top" ekusethweni kwejika lokushisa kwesithando somlilo

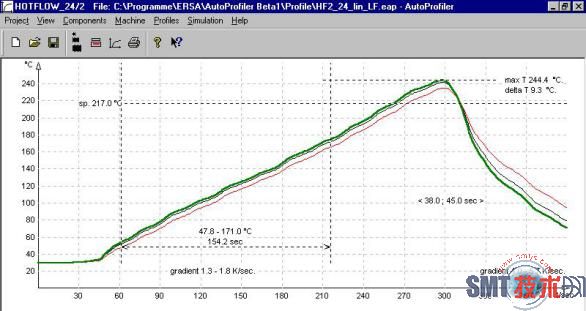

Uma izingxenye zangempela ebhodini lesifunda zinomehluko omncane kumthamo oshisayo kodwa zizwela kakhulu ukushaqeka kokushisa, kufaneleka kakhulu ukusebenzisa ijika lokushisa "elinomugqa" lomlilo.(Bheka umfanekiso 10)

Umfanekiso 10 “Linear” ijika lokushisa lesithando somlilo

Ukusethwa nokulungiswa kwezinga lokushisa kwesithando somlilo kuncike ezintweni eziningi ezifana nemishini, izingxenye zangempela, i-solder paste, njll. Indlela yokusetha ayifani, futhi ulwazi kufanele luqoqwe ngokuhlolwa.

l Isofthiwe yokulingisa ijika lesithando somlilo

Ngakho-ke ingabe zikhona izindlela ezingasisiza ngokushesha nangokunembile ukusetha ijika lokushisa lesithando somlilo?Singacabangela ukukhiqiza isofthiwe ngosizo lokulingisa ijika lesithando somlilo.

Ngaphansi kwezimo ezijwayelekile, inqobo nje uma sitshela isofthiwe isimo sebhodi lesifunda, isimo sedivayisi yokuqala, isikhawu sebhodi, isivinini seketango, ukulungiselelwa kwezinga lokushisa nokukhethwa kwemishini, isofthiwe izolingisa ijika lezinga lokushisa elikhiqiziwe. ngaphansi kwezimo ezinjalo.Lokhu kuzolungiswa kungaxhunyiwe ku-inthanethi kuze kutholakale ijika lezinga lokushisa eligculisayo lesithando somlilo.Lokhu kungasindisa kakhulu isikhathi sokuba onjiniyela bezinqubo balungise ngokuphindaphindiwe ijika, okubaluleke kakhulu kubakhiqizi abanezinhlobonhlobo eziningi namaqoqo amancane.

Ikusasa lobuchwepheshe be-reflow soldering

Imikhiqizo yomakhalekhukhwini kanye nemikhiqizo yezempi inezidingo ezihlukene zokuphinda kufakwe i-solder, futhi ukukhiqizwa kwebhodi lesifunda kanye nokukhiqizwa kwe-semiconductor kunezidingo ezihlukene zokuphinda kufakwe i-solder.Ukukhiqizwa kwezinhlobonhlobo ezincane kanye nevolumu enkulu kwaqala ukwehla kancane kancane, futhi umehluko wezidingo zemishini yemikhiqizo ehlukene waqala ukuvela usuku nosuku.Umehluko phakathi kwe-reflow soldering esikhathini esizayo ngeke ubonakale kuphela enanini lezindawo zokushisa kanye nokukhethwa kwe-nitrogen, imakethe ye-reflow soldering izoqhubeka nokuhlukaniswa, okuyisiqondiso sokuthuthukiswa okubonakalayo kobuchwepheshe bokuthengisa kabusha ngokuzayo.

Isikhathi sokuthumela: Aug-14-2020