Ukuze kuhlangatshezwane nezidingo ezishisayo zohlelo lokusebenza, abaklami badinga ukuqhathanisa izici ezishisayo zezinhlobo zephakheji ze-semiconductor ezihlukene.Kulesi sihloko, i-Nexperia ixoxa ngezindlela ezishisayo zamaphakheji ayo ebhondi yezintambo namaphakheji ebhondi ye-chip ukuze abaklami bakwazi ukukhetha iphakheji elifaneleka kakhudlwana.

Indlela Ukuqhuba Okushisayo Kuzuzwa Ngayo Kumadivayisi Axhunywe Ngentambo

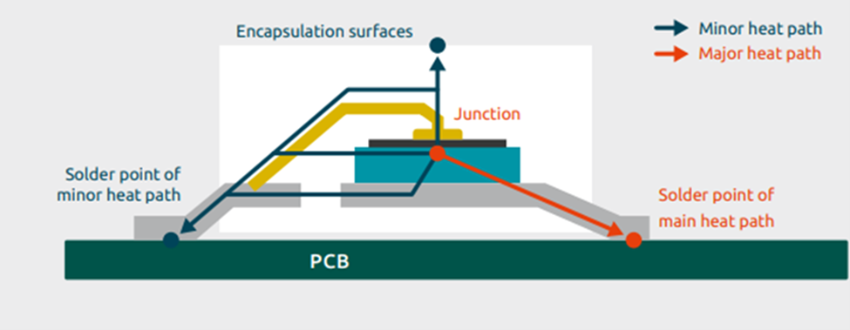

Isinki sokushisa esiyinhloko kudivayisi eboshwe ngentambo sisuka endaweni eyireferensi ye-junction kuya kumajoyinti e-solder ebhodini lesekethe eliphrintiwe (PCB), njengoba kuboniswe kuMfanekiso 1. Kulandelwa i-algorithm elula yokulinganisa kwe-oda lokuqala, umphumela wamandla wesibili. isiteshi esisetshenziswayo (esiboniswe emfanekisweni) alinakwa ekubalweni kokumelana nokushisa.

Amashaneli ashisayo kumadivayisi ahlanganiswe ngentambo

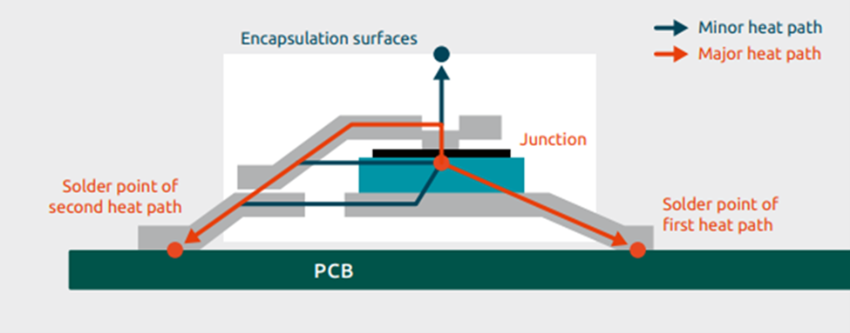

Amashaneli e-dual conduction ashisayo kudivayisi ye-SMD

Umehluko phakathi kwephakheji ye-SMD kanye nephakheji eboshwe ngocingo mayelana nokukhishwa kokushisa ukuthi ukushisa okuvela lapho kuhlangana khona idivayisi kungahlakazwa ngamashaneli amabili ahlukene, okungukuthi, ngohlaka lomthofu (njengamaphakheji ahlanganiswe ngocingo) futhi ngohlaka lwesiqeshana.

Ukudlulisa ukushisa kuphakheji eboshwe nge-chip

Incazelo yokumelana okushisayo kwe-junction kuya ku-solder joint Rth (j-sp) iphinde ibe nzima ngokuba khona kwamajoyinti amabili e-solder.Lawa maphoyinti ereferensi angase abe namazinga okushisa ahlukene, okubangela ukumelana nokushisa kube inethiwekhi ehambisanayo.

I-Nexperia isebenzisa indlela efanayo ukuze ikhiphe inani le-Rth(j-sp) kuwo womabili amadivayisi ahlanganiswe ne-chip nathengiswa ngocingo.Leli nani libonisa indlela eshisayo eyinhloko esuka ku-chip iye kuhlaka oluholayo kuya emajoyintini e-solder, okwenza amanani wamadivayisi ahlanganiswe ne-chip afane namanani wamadivayisi athengiswa ngocingo kusakhiwo esifanayo se-PCB.Nokho, isiteshi sesibili asisetshenziswa ngokugcwele lapho kukhishwa inani le-Rth(j-sp), ngakho-ke wonke amandla okushisa edivayisi ngokuvamile aphezulu.

Eqinisweni, isiteshi sesibili sokucwilisa ukushisa esibucayi sinikeza abaklami ithuba lokuthuthukisa idizayini ye-PCB.Isibonelo, ngocingo oluthengiswa ngocingo, ukushisa kungachithwa kuphela ngesiteshi esisodwa (iningi lokushisa kwe-diode lichithwa ngephinikhodi ye-cathode);kudivayisi eboshwe ngesiqeshana, ukushisa kungahlakazwa kuwo womabili amatheminali.

Ukulingisa Ukusebenza Okushisayo Kwamadivayisi E-Semiconductor

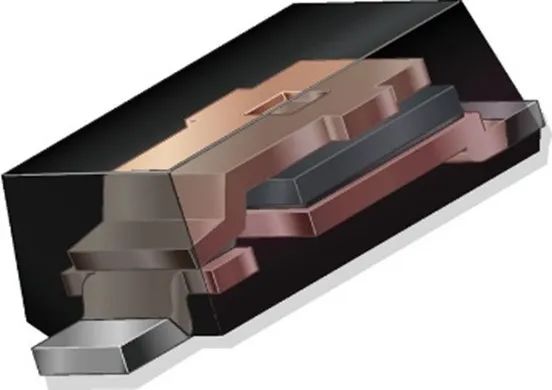

Ukuhlolwa kokulingisa kubonise ukuthi ukusebenza kwe-thermal kungathuthukiswa kakhulu uma wonke amatheminali wedivayisi ku-PCB enezindlela ezishisayo.Isibonelo, ku-CFP5-packaged PMEG6030ELP diode (Umfanekiso 3), u-35% wokushisa udluliselwa kumaphini we-anode ngokusebenzisa izinsimbi zethusi bese u-65% udluliselwa kumaphini we-cathode ngokusebenzisa ama-leadframe.

I-CFP5 diode ehlanganisiwe

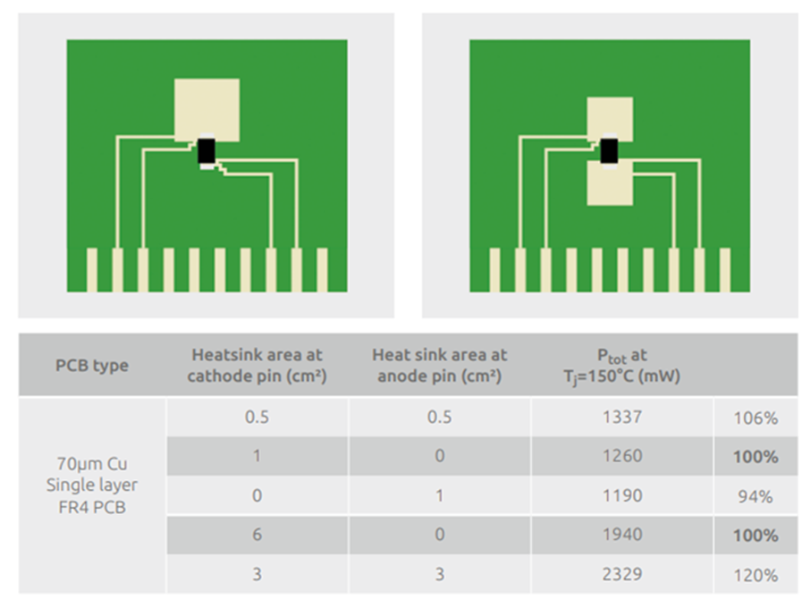

"Ukuhlolwa kokulingisa kuqinisekisile ukuthi ukuhlukanisa isinki sokushisa zibe izingxenye ezimbili (njengoba kuboniswe kuMfanekiso 4) kulungele kakhulu ukuqeda ukushisa.

Uma i-heatsink engu-1 cm² ihlukaniswa ibe amaheatsink amabili angu-0.5 cm² abekwe ngaphansi kwetheminali ngayinye kwamabili, inani lamandla elingachithwa yi-diode ngezinga lokushisa elifanayo lenyuka ngo-6%.

Amaheatsink amabili angu-3 cm² akhuphula ukuchithwa kwamandla cishe ngamaphesenti angu-20 uma kuqhathaniswa nomklamo ojwayelekile wokucwilisa ukushisa noma i-heatsink engu-6 cm² enamathiselwe kuphela ku-cathode.”

Imiphumela Yokulingisa Okushisayo Ngosinki Wokushisa Ezindaweni Ezihlukene Nezindawo Zebhodi

I-Nexperia Isiza Abaklami Bakhethe Amaphakheji Afaneleka Kangcono Izicelo Zabo

Abanye abakhiqizi bedivayisi ye-semiconductor ababahlinzeki abaklami ngolwazi oludingekayo ukuze banqume ukuthi yiluphi uhlobo lwephakheji oluzohlinzeka ngokusebenza okungcono okushisayo kohlelo lwabo lokusebenza.Kulesi sihloko, i-Nexperia ichaza izindlela ezishisayo kumadivayisi ayo ahlanganisiwe ne-chip ukusiza abaklami benze izinqumo ezingcono zezinhlelo zabo zokusebenza.

Amaqiniso asheshayo nge-NeoDen

① Isungulwe ngo-2010, abasebenzi abangu-200+, 8000+ Sq.m.ifektri

② Imikhiqizo ye-NeoDen: I-Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder unama iphrinta FP26406, 3 PM

③ Amakhasimende angu-10000+ aphumelele emhlabeni wonke

④ 30+ ama-Global Agents ambozwe e-Asia, Europe, America, Oceania nase-Afrika

⑤ Isikhungo se-R&D: Iminyango emi-3 ye-R&D enonjiniyela abangu-25+ be-R&D abangochwepheshe

⑥ Ifakwe ohlwini lwe-CE futhi yathola amalungelo obunikazi angama-50+

⑦ 30+ onjiniyela bokulawula ikhwalithi nokusekelwa kobuchwepheshe, ukuthengiswa kwamazwe ngamazwe okuphezulu okungu-15+, ikhasimende elifika ngesikhathi liphendula phakathi kwamahora angu-8, izixazululo ezichwepheshile ezihlinzeka phakathi kwamahora angu-24

Isikhathi sokuthumela: Sep-13-2023